By Futurist Thomas Frey

The Performance Nobody Expected to See

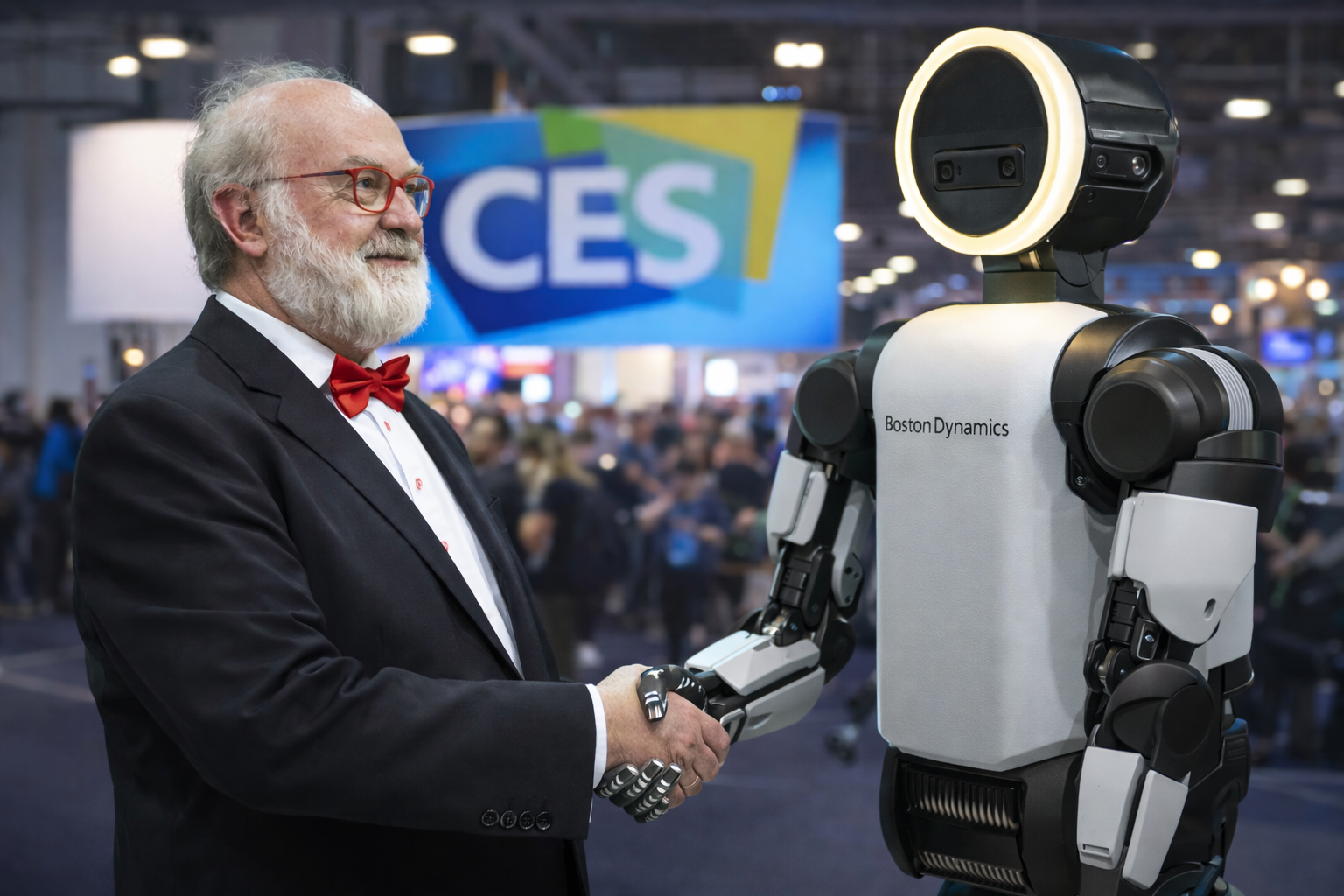

For the first time ever, a major robotics company did something unthinkable: they demonstrated a humanoid robot live, in public, without editing, without safety nets, where failure would be witnessed by hundreds of industry analysts and instantly amplified across global media.

“For the first time ever in public, please welcome Atlas to the stage,” said Boston Dynamics’ Zachary Jackowski at CES 2026 in Las Vegas. The life-sized robot picked itself up from the floor, walked fluidly across the stage for several minutes, waved to the crowd, and swiveled its head like an owl. No stumbles. No falls. No frantic engineers rushing to intervene.

The demonstration itself was modest—Atlas was remotely piloted for the showcase. But the symbolism was massive. Robotics companies almost never demonstrate humanoids live because fumbles attract catastrophic attention. Russia’s first humanoid face-planted in November. That’s why everyone releases carefully edited videos on social media—maximum control, zero risk.

Boston Dynamics just threw that playbook away. And by doing so, they signaled something fundamental: Atlas isn’t a research prototype anymore. It’s becoming a product. And Hyundai isn’t experimenting with humanoid labor—they’re committing to it at industrial scale.

Let me walk you through why this CES demonstration represents inflection point where humanoid robots transition from impressive demonstrations to deployed infrastructure, what becomes possible when manufacturing commits to human-form automation, and why the timeline to mass adoption just accelerated dramatically.

What Makes Atlas Different

This isn’t Boston Dynamics’ first Atlas. The company’s been developing humanoid robots for over a decade—originally hydraulic systems funded by DARPA, then electric prototypes showcased doing parkour and gymnastics in viral videos.

But the Atlas unveiled at CES is fundamentally different. It’s production-oriented rather than research-focused. Every component was designed for compatibility with automotive supply chains. The entire system prioritizes manufacturing reliability over demonstration capability.

The specifications tell the story:

56 degrees of freedom with fully rotational joints—most can spin 360 degrees, enabling inhuman range of motion that actually proves advantageous for industrial tasks. Human-scale hands with tactile sensing for precision manipulation. 110-pound lifting capacity for substantial manufacturing components. 7.5-foot reach extending its working envelope. Four-hour battery life with autonomous battery swapping for continuous 24/7 operation.

Water resistance rated IP67—it can handle industrial washdowns. Temperature tolerance from -4°F to 104°F—it works in harsh factory conditions. Height 6.2 feet, resembling human proportions for existing workspace compatibility.

Most critically: trainable for most tasks in under one day. Not months of programming—single day of training using imitation learning where Atlas watches humans perform tasks and replicates them.

This is engineered product, not laboratory prototype. And Hyundai’s putting it to work in 2028 at their electric vehicle plant near Savannah, Georgia—the same plant that was site of federal immigration raid arresting hundreds of workers in 2024.

That timing isn’t coincidental.

The Deployment Strategy: How Hyundai Actually Plans to Use Atlas

Hyundai isn’t dropping humanoid robots into assembly lines hoping they figure things out. They’ve architected comprehensive deployment strategy that reveals how serious they are about making this work.

Phase 1 (2028): Parts Sequencing Atlas starts with highest-value, lowest-complexity tasks—organizing components in the order they’re installed in vehicles. This is physically demanding, repetitive, injury-prone work that humans hate. It’s also relatively structured with predictable patterns, making it ideal for initial deployment.

Success here means Atlas proves it can handle materials reliably without damaging components or endangering human coworkers. It establishes safety protocols, identifies training improvements, builds confidence.

Phase 2 (2030): Component Assembly After two years proving reliability in sequencing, Atlas graduates to actual assembly operations—installing parts, fastening components, quality verification. This requires significantly more dexterity and decision-making but leverages lessons learned from earlier deployment.

Phase 3 (2030-2035): Complex Tasks Eventually, Atlas handles heavy lifting, intricate assembly, dangerous operations, and tasks requiring the flexibility that humanoid form factor enables—reaching into tight spaces, manipulating tools designed for human hands, adapting to situations that don’t fit rigid automation.

The Infrastructure Behind It:

Hyundai’s building Robot Metaplant Application Center (RMAC) opening in 2026—dedicated training facility where Atlas learns human collaboration patterns before deploying to actual production floors. Data from RMAC feeds Software-Defined Factory platforms, creating continuous improvement loop where every Atlas across the network learns from collective experience.

They’re building new robotics factory in the US capable of producing 30,000 robot units annually by 2028. That’s not pilot program scale—that’s commitment to mass deployment across Hyundai’s global manufacturing network.

Hyundai Mobis develops high-performance actuators and components. Hyundai Glovis handles logistics optimization and supply chain management. The entire corporate ecosystem is oriented toward making humanoid manufacturing succeed.

The Google DeepMind Partnership: When Robots Get Foundation Models

Perhaps most significant announcement at CES: Hyundai and Boston Dynamics partnered with Google’s DeepMind to integrate Gemini Robotics foundation models into Atlas.

This is reunion—Google bought Boston Dynamics in 2013, sold it to SoftBank years later, and Hyundai acquired it in 2021 for $880 million. Now Google’s back, but bringing something they didn’t have last time: sophisticated AI that enables robots to perceive environments, reason through problems, and adapt to unpredictable situations.

Foundation models change everything. Instead of programming specific behaviors for specific tasks, you train general-purpose intelligence that figures out how to accomplish objectives in varied contexts. Atlas won’t just follow predefined routines—it will understand what needs to happen and determine how to make it happen.

Nvidia’s also involved, providing AI infrastructure and simulation tools. South Korea’s Ministry of Science and ICT is coordinating with Hyundai and Nvidia to strengthen national Physical AI capabilities. This isn’t startup betting on robotics—it’s converging interests of major technology companies, automotive manufacturers, and national governments all aligned on humanoid automation succeeding.

What This Means for Manufacturing and Employment

Hyundai frames this as “human-centered automation”—robots handle labor-intensive and high-risk work while humans retain control, training systems and supervising operations.

That framing is simultaneously accurate and incomplete.

What’s definitely true: Atlas takes on dangerous tasks humans shouldn’t do—heavy lifting that causes repetitive stress injuries, operations in extreme temperatures, exposure to hazardous materials, precision assembly that strains vision and causes long-term damage.

What’s also true: Every Atlas deployed is job that no longer requires human. The Savannah plant employing Atlas in 2028 was raided in 2024 with hundreds of workers arrested. That plant will have significantly fewer human employees by 2030, not because jobs were offshored but because they were automated.

McKinsey consultant Alex Panas, speaking at CES robotics panel, framed it carefully: “Humanoids don’t yet have enough dexterity to threaten many human jobs, though a debate over their effects on employment is likely to grow as they become more skilled.”

That “yet” is load-bearing word. And “as they become more skilled” is happening faster than most people realize, accelerated by foundation models enabling rapid learning rather than slow programming.

Hyundai expects humanoids to become largest segment of Physical AI market. They’re planning to produce 30,000 units annually by 2028. That’s not far-future speculation—it’s near-term industrial strategy.

Why the Live Demonstration Matters More Than the Technology

The actual technology showcased at CES wasn’t revolutionary. Boston Dynamics has been developing Atlas for over a decade. We’ve seen videos of it doing backflips, running parkour courses, performing simulated factory work.

What changed is that they demonstrated it live, publicly, where failure would be immediate and visible.

That signals confidence. Not in individual robot’s capabilities but in technology’s reliability at scale. You don’t risk public demonstration unless you’re certain your system works consistently enough that live showcase won’t become disaster.

And you don’t announce 2028 deployment with 30,000 annual production capacity unless you’ve solved the hard problems: cost, reliability, safety, training efficiency, supply chain integration.

The viral robot videos were impressive. This is different. This is commitment.

The Competition Intensifies

Atlas isn’t alone. Tesla’s developing Optimus humanoid, though current capabilities remain far behind Atlas. Figure AI, backed by OpenAI and Nvidia, is building commercial humanoids. Sanctuary AI, Apptronik, Agility Robotics—all racing to deploy human-form robots in industrial settings.

But Hyundai has unique advantages: manufacturing expertise at massive scale, automotive supply chains that can produce complex mechatronic systems affordably, real factories where robots can be tested and deployed immediately, and financial capacity to invest billions in robotics infrastructure.

Boston Dynamics’ Spot quadruped robot already operates in industrial inspections and safety applications. Their Stretch warehouse robot has unloaded over 20 million boxes globally since launching in 2023. They know how to transition from research to commercial deployment. Atlas is next.

The question isn’t whether humanoid robots work in factories. It’s how fast they scale from experimental to ubiquitous.

The Timeline We’re Actually Looking At

2026: RMAC training center opens, Atlas units undergo intensive development and safety validation in controlled environments.

2027: Pre-deployment testing in actual factory conditions, refining training processes and human-robot collaboration protocols.

2028: Initial Atlas deployment in Savannah plant handling parts sequencing, first commercial humanoid operations at scale.

2029: Expansion to additional Hyundai facilities, deployment numbers increase from dozens to hundreds as production ramps.

2030: Component assembly operations begin, Atlas transitions from material handling to actual manufacturing tasks, deployment reaches thousands of units globally.

2030-2035: Rapid proliferation across automotive manufacturing, other industries adopt humanoid automation as costs decline and capabilities expand, market reaches tens of thousands of units annually.

2035-2040: Humanoid robots become standard manufacturing infrastructure, comparable to industrial robot arms today, employment in repetitive physical labor declines dramatically.

This isn’t speculative timeline. Hyundai’s publicly committed to these milestones. Production capacity is being built. Partnerships are formalized. Investment is allocated.

Final Thoughts

Atlas stood up at CES, walked across the stage, and waved. Simple demonstration. But symbolic moment when humanoid robots stopped being impressive research and started being industrial reality.

The technology’s been developing for over a decade. What changed is that manufacturing committed to deploying it at scale, with timelines, production capacity, and billions in investment backing that commitment.

This doesn’t mean humanoids are ready for homes, hospitals, or retail environments. Boston Dynamics CEO Robert Playter explicitly said they’re not pursuing home deployment now—costs are too high, capabilities insufficient, safety standards non-existent.

But factories? Factories are different. Structured environments, defined tasks, economic justification for expensive robots, existing safety protocols for industrial automation. That’s where humanoid deployment begins.

And once it begins in manufacturing, costs decline through scale, capabilities improve through deployment experience, and applications expand into logistics, construction, agriculture, anywhere physical labor happens in structured-enough environments.

Atlas walking across CES stage wasn’t the future arriving. It was confirmation the future is already here—just not evenly distributed yet. By 2028, it will be assembling Hyundai vehicles in Georgia. By 2035, it will be working in factories worldwide. By 2040, human-form robots performing physical labor will be unremarkable rather than astonishing.

We just watched the inflection point happen live on stage. And unlike most humanoid demonstrations, this one wasn’t carefully edited video. It was real robot, real time, real commitment to making this work at industrial scale.

The age of humanoid labor didn’t start at CES. But that’s where it stopped being future speculation and became industrial strategy.

Related Articles:

Boston Dynamics Unveils New Atlas Robot to Revolutionize Industry https://bostondynamics.com/blog/boston-dynamics-unveils-new-atlas-robot-to-revolutionize-industry/

Nvidia CEO Jensen Huang: ‘The ChatGPT Moment for Robotics Is Here’ https://www.euronews.com/next/2026/01/06/future-of-autonomous-driving-and-robots-just-went-up-a-gear-nvidia-and-boston-dynamics-ces

The $2 Billion Daily Question: Where’s Your Piece of the AI Future? https://www.impactlab.com/2026/01/06/2-billion-daily-question-ai-future/

Claude is AI and can make mistakes.

Please double-check cited sources.