A research team at the University of Texas at Austin has developed a groundbreaking 3D printing process that, for the first time, enables the precise integration of soft and hard materials within a single printed component—without introducing mechanical weaknesses where the two properties meet. This innovation, recently published in Nature Materials, marks a major advancement in additive manufacturing.

The method uses a specially formulated photopolymer resin matrix and a dual-exposure approach, employing two distinct wavelengths of light to control material properties at a microscopic level. Violet light initiates a reaction that forms a soft, elastomer-like structure, while higher-energy ultraviolet (UV) light triggers a separate reaction that creates a rigid, thermoplastic-like material. By controlling exposure to each wavelength during the printing process, researchers can seamlessly transition between soft and hard regions within a single object.

Central to this capability is a custom-designed molecule that features two different reactive groups. These groups enable the material to form strong chemical bonds across the soft-hard interface, preventing the delamination or weak points that typically occur in multi-material prints. The system can even be tuned to create gradual transitions between stiffness levels, mimicking how natural materials like cartilage or tendons connect to bone.

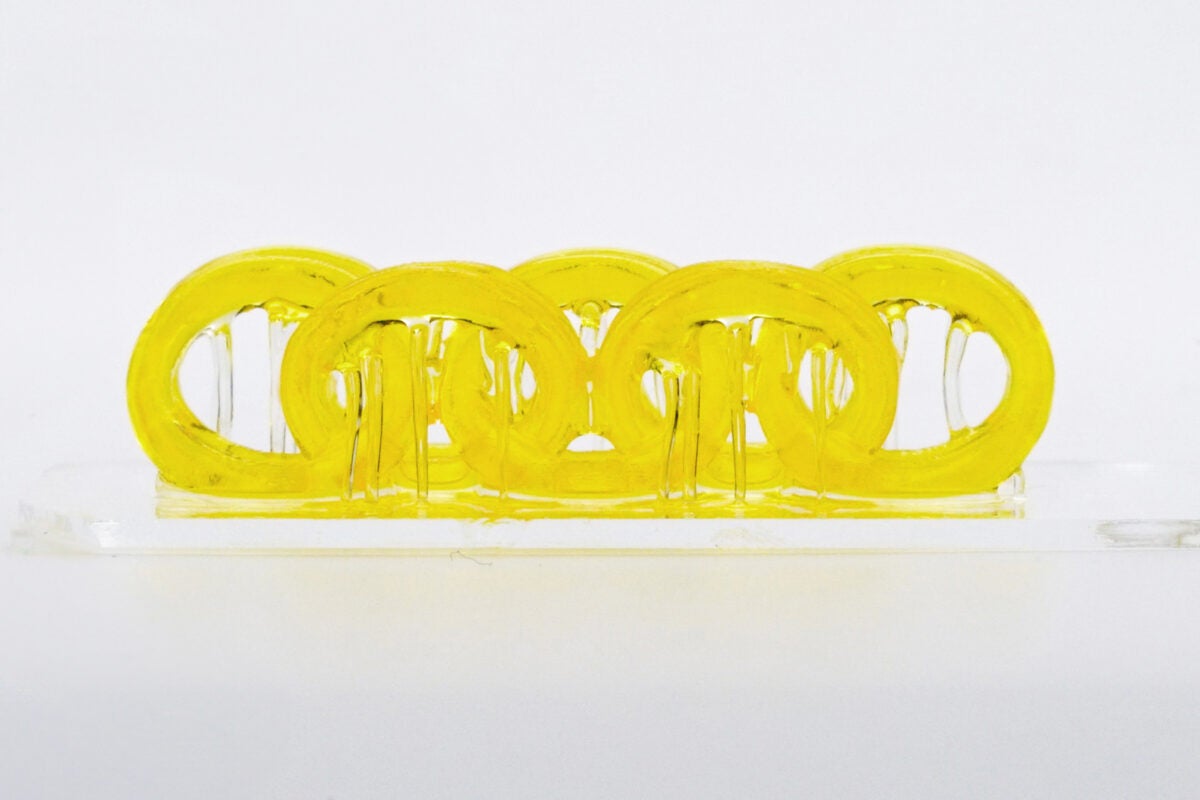

Inspired by nature’s ability to integrate diverse materials seamlessly, the researchers demonstrated the technology’s potential with several prototypes. One example includes a functional knee joint composed of flexible ligaments and rigid, bone-like supports. Another prototype featured a stretchable electronic circuit with a gold-coated wire that remains flexible in one section while providing mechanical support in another.

This new technique could significantly broaden the capabilities of 3D printing in fields such as biomedical engineering, wearable electronics, soft robotics, and prototyping. It also has potential to compete with traditional manufacturing techniques like injection molding, offering not only versatility in design but also faster production and reduced complexity.

The process is compatible with relatively simple hardware and offers rapid curing, making it accessible for research and medical applications. A patent has been filed for the technology, which has received support from the U.S. Department of Defense and the National Science Foundation.

By Impact Lab