For more than a century, superconductors have represented one of science’s most tantalizing frontiers: materials capable of conducting electricity with zero resistance. They are the backbone of MRI machines, particle accelerators, and the dream of next-generation quantum devices. But until now, the process of making them has been slow, rigid, and rooted in decades-old methods. That just changed. Cornell researchers have unveiled a one-step 3D-printing process that doesn’t just simplify how superconductors are made—it unlocks unprecedented performance, shattering records with magnetic field strengths of 40 to 50 Tesla. To put that in perspective, the magnets used at CERN’s Large Hadron Collider peak around 8 Tesla. Cornell’s breakthrough isn’t just incremental; it’s transformative.

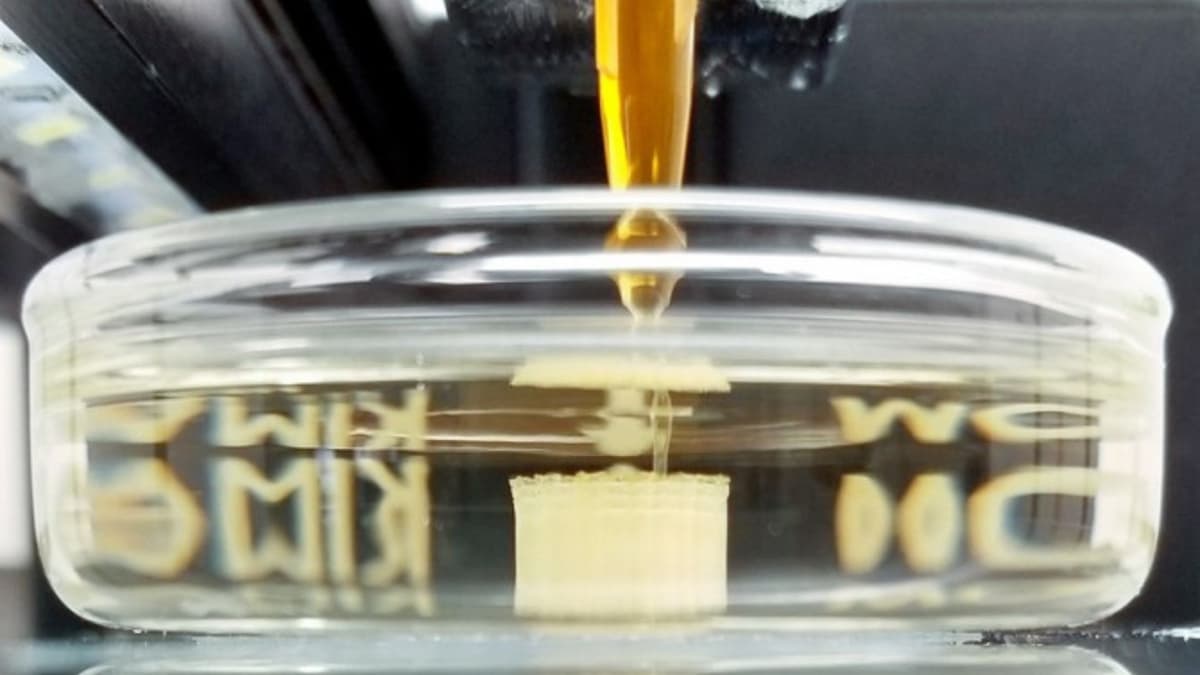

The secret lies in a unique “superconductor ink” made from copolymers and nanoparticles. When printed, the material self-assembles into an intricate hierarchy: crystalline lattices at the atomic scale, mesostructures formed by the copolymer organization, and macroscopic 3D shapes like coils and helices. A subsequent heat treatment converts these structures into porous superconductors with properties that traditional fabrication could never achieve. This so-called “one-pot” method eliminates countless manufacturing steps—no powders, binders, or repeated heating cycles. The result is a superconductor not only easier to make but structurally superior, optimized down to the nanoscale for maximum performance.

The most striking outcome came from niobium nitride, a well-studied material suddenly supercharged by this approach. Thanks to the porous nanostructure, its upper critical magnetic field soared to a record 50 Tesla—the highest ever reported for this compound. That leap is more than academic. It means superconducting magnets could become stronger, more efficient, and more compact, opening doors to breakthroughs in medical imaging, energy transmission, fusion reactors, and quantum information systems. Graduate students Fei Yu and Paxton Thetford, who helped crack the chemistry and ink design, demonstrated just how quickly a new generation of scientists is pushing materials science into uncharted territory.

What makes this discovery provocative is not just the record-breaking numbers but the way it reframes material design itself. By mapping superconducting properties to polymer parameters, the Cornell team has shown that we can design performance into materials before they even exist. That means the future of superconductors may not depend on rare discoveries or trial-and-error experimentation, but on programmable design rules. Superconductors could soon be engineered like software, with researchers dialing in desired properties and printing them on demand.

The implications stretch well beyond magnets and medical scanners. Imagine 3D-printed superconducting circuits designed specifically for quantum computers, architectures impossible with conventional manufacturing. Imagine flexible, lightweight superconducting coils embedded into vehicles, drones, or wearable technologies. Even fusion energy, often dismissed as “always 30 years away,” could take a leap forward with magnets powerful enough to confine plasma more efficiently. The same technology that produced a dime-sized test coil in the lab could one day build kilometer-scale energy systems.

Cornell’s researchers are already looking to expand the method to other compounds like titanium nitride and to explore exotic geometries that could unlock entirely new phases of quantum matter. The porous structures they’ve demonstrated also provide vast surface areas, ideal for pushing the boundaries of superconducting chemistry. What was once considered a hard, brittle, and unforgiving class of materials is now being reshaped—literally—through soft-matter approaches and design thinking.

Superconductors have always carried an aura of inevitability: someday, they would revolutionize energy and computing. That “someday” may just have been pulled dramatically closer. A century from now, historians may look back and see this as the turning point when superconductors shifted from being rare and exotic to being printable, scalable, and ubiquitous. The power grid, medical systems, transportation, and computation may all run on the foundation being laid by this breakthrough.

We are entering an age where materials are no longer discovered—they are engineered. Cornell’s 3D-printed superconductor is not just a scientific triumph but a glimpse of the future where quantum materials are designed like art and fabricated at will. The barriers that defined the last century of materials science are beginning to collapse, and with them, the limitations on what we can build. The race for the superconducting century has begun.

Read more on related breakthroughs:

- 3D printing ushers in new possibilities for superconducting devices

- Programmable materials bring quantum breakthroughs closer