For centuries, metallurgy has been a slow, brute-force art—smelting, mixing, hammering, and hoping the end product has the right properties. But Caltech scientists have just detonated that tradition with a breakthrough that turns metalmaking into a precision craft, letting researchers dial in alloy compositions like a DJ spinning tracks.

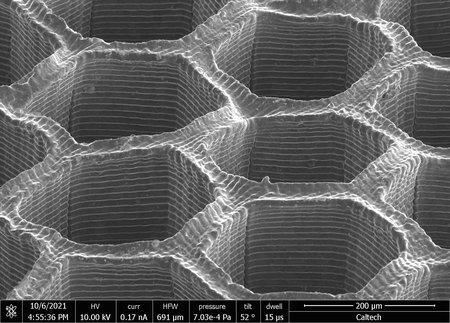

Their new approach, an extension of hydrogel-infusion additive manufacturing (HIAM), doesn’t just make parts—it engineers metal at the atomic scale. The process starts with a 3D-printed hydrogel scaffold, which is soaked in metallic salt solutions. The hydrogel burns away in a high-heat calcination process, leaving behind metal oxides. Then, under a hydrogen-rich environment, oxygen is stripped out and the final alloy emerges—dense, strong, and shaped exactly as designed.

Continue reading… “Metal Alchemy at the Speed of Light: Caltech’s 3D Printing Breakthrough Rewrites the Rules of Alloy Design”