A team of researchers from Saarland University and the Center for Mechatronics and Automation Technology (ZeMA) in Germany has introduced a groundbreaking air conditioning technology that could transform the way we cool and heat spaces, offering substantial energy savings and environmental benefits. This novel system harnesses the “elastocaloric effect” in nickel-titanium (Ni-Ti) shape memory alloys to cool and heat without relying on volatile refrigerants or burning fossil fuels.

The technology, dubbed elastocalorics, represents a cleaner, more sustainable alternative to conventional air conditioning systems. Unlike traditional methods, elastocaloric systems are only as polluting as the electricity that powers them, making them significantly more eco-friendly. The system’s energy efficiency and environmentally safe design have already garnered international attention, with the European Commission recognizing it as a leading alternative to standard cooling systems. Additionally, the World Economic Forum ranked elastocalorics among its “Top Ten Emerging Technologies” for 2024.

Professors Stefan Seelecke and Paul Motzki, pioneers in the field of elastocaloric technology, explain that their prototypes demonstrate how repeated mechanical deformation of ultrathin Ni-Ti wires or sheets can efficiently move heat from one place to another. The key to this system lies in the “shape memory” property of nickel-titanium. When the material is stretched (placed under tension), it absorbs heat. When the tension is released, the material reverts to its original phase and releases the stored heat elsewhere. This process allows the system to heat or cool air (or other media like water-glycol mixes) in a highly controllable manner, offering greater energy efficiency than conventional air conditioners or heat pumps.

The engineers at Saarbrücken have developed prototypes that stretch and relax these Ni-Ti wires or sheets in cycles, transferring heat to or from a flowing medium like air, and running continuously without relying on traditional refrigerants. This eliminates the environmental risks associated with standard refrigerants while significantly improving overall energy efficiency.

Elastocaloric technology has vast potential across various industries. Government bodies and corporate stakeholders, including Volkswagen and the Fraunhofer Institute, are already collaborating with the research team to explore applications for electric vehicles (EVs), residential buildings, and other sectors.

The team is developing several key prototypes, such as a lightweight air-conditioning unit for electric cars and a system that cools EV traction batteries. For residential buildings, they are engineering a compact version that can heat or cool rooms using vents in outer walls. Initial trials suggest that single-stage elastocaloric systems can achieve temperature differentials of around 36°F (20°C), with multi-stage solutions capable of even greater temperature variations.

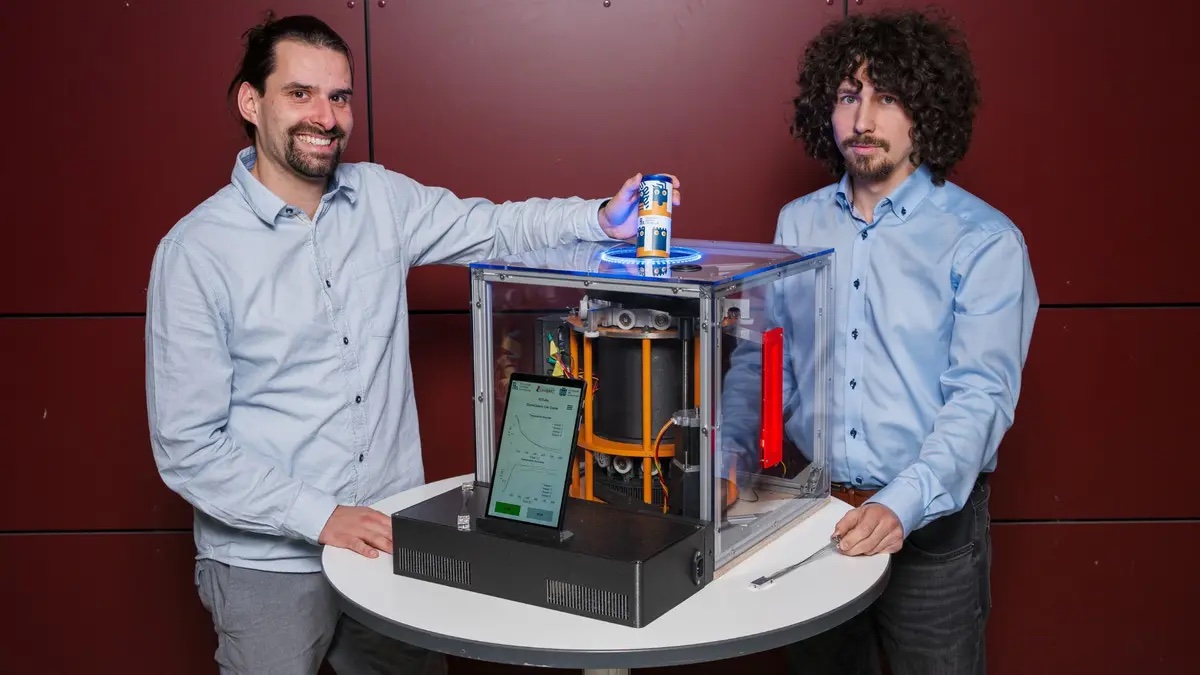

Elastocaloric technology is rapidly advancing toward commercial viability. With more than €17 million invested in a dedicated project, alongside an additional €3.5 million in government funding, the technology is poised for large-scale production. The researchers’ progress builds on over 15 years of work, which has already resulted in the creation of the world’s first continuous air-to-air elastocaloric prototype and a mini fridge powered by elastocaloric cooling.

At Hannover Messe, the team showcased a rotating cam-track fridge powered by 200-micron-thin Ni-Ti wire bundles that are continuously tensioned and released. As the wires move in and out of the cooling chamber, they steadily transfer heat. The system also employs self-sensing technology, supported by artificial intelligence, to monitor wire deformation and maintain precise control.

By combining cutting-edge materials science with practical engineering, the Saarland University team is paving the way for a future where climate control is safer, cleaner, and more energy-efficient. Their elastocaloric systems promise to revolutionize an industry responsible for a significant portion of global energy use, offering a path toward more sustainable heating and cooling solutions for homes, vehicles, and beyond. This breakthrough technology could play a pivotal role in reducing the environmental impact of traditional air conditioning and heating systems worldwide.

By Impact Lab