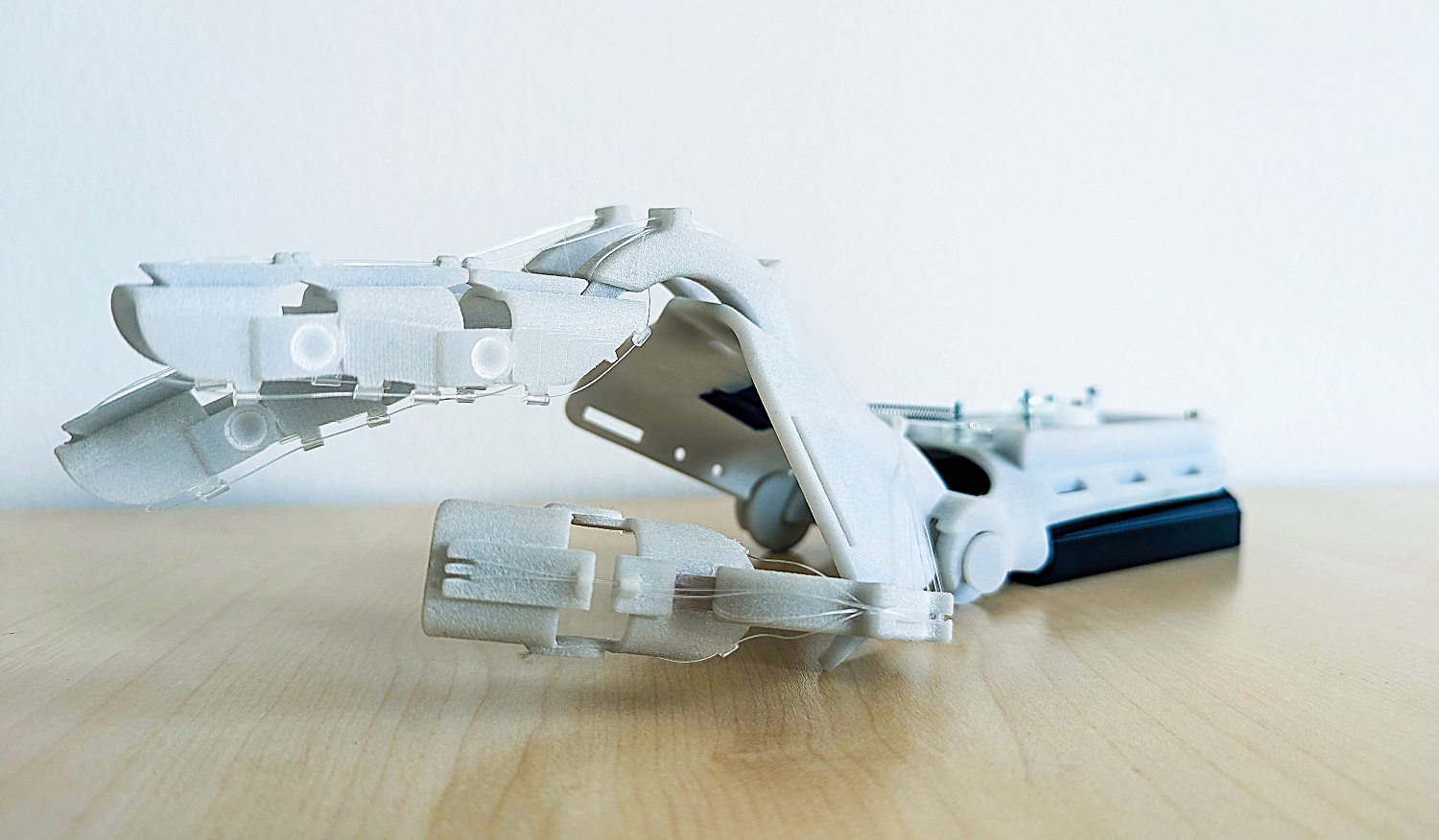

At first glance, it looks like something out of a cyberpunk film—a sleek, skeletal glove clinging to your hand like a second skin. But this isn’t science fiction. At Germany’s Fraunhofer Institute for Machine Tools and Forming Technology (IWU), researchers are engineering custom 3D-printed exoskeletons that adapt to your exact hand shape, strength profile, and even your injury history.

The concept is deceptively simple: combine a precise 3D scan of your hand with parametric CAD design and selective laser sintering (SLS) to print an exoskeleton that matches your anatomy, not some average model. Every curve, joint angle, and finger length is taken into account. No two devices are the same—because no two hands are the same.

But the magic isn’t just in the fit. The real breakthrough lies in the exoskeleton’s artificial tendons, powered by a bidirectional stepper motor and shape memory alloy (SMA) wires. When heated, these wires contract with precision, translating thermal energy into controlled, repeatable motion. That means your device can fine-tune both force and range of motion for each finger independently. It doesn’t just move your hand—it moves your hand, exactly the way you need it to.

The feedback loop built into the system allows it to support dynamic, real-world movements—gripping a water bottle, typing on a keyboard, or even playing a musical instrument. And because it can run without constant supervision, it’s ideal for high-intensity rehab sessions where repetition is key, such as recovery after tendon injuries, paralysis, or stroke.

By blending additive manufacturing with biomechanical intelligence, the Fraunhofer IWU team isn’t just making rehab gear—they’re redefining what a prosthetic or therapeutic device can be. In the future, “off-the-shelf” may become obsolete, replaced by personalized bionics that fit and function like they were part of you all along.

Related stories on personalized exoskeletons and biomechanics:

- 3D-Printed Wearable Tech That Molds to Your Body

- Robotic Exoskeletons Are Giving Stroke Patients a Second Chance