The future of sensing technology may not lie in better electronics, but in stranger geometry. Auxetic metamaterials—structures that do the opposite of what we expect when squeezed—are now stepping into the spotlight. Instead of bulging outward when compressed, they contract inward, concentrating strain in ways nature almost never does. For decades, this quirk of physics was a lab curiosity. Now, thanks to 3D printing, auxetic designs are powering a new class of tactile sensors with applications in robotics, healthcare, and wearable technology.

A research team from Seoul National University of Science and Technology has developed a 3D-printed tactile sensing platform that takes advantage of this counterintuitive behavior. Their breakthrough design—a cubic lattice with carefully patterned spherical voids—was built using digital light processing, a high-precision form of 3D printing. What makes it different is not just the geometry, but how it reshapes sensor performance itself. The inward contraction concentrates strain where it’s needed, boosting sensitivity, improving stability, and reducing interference between sensing units.

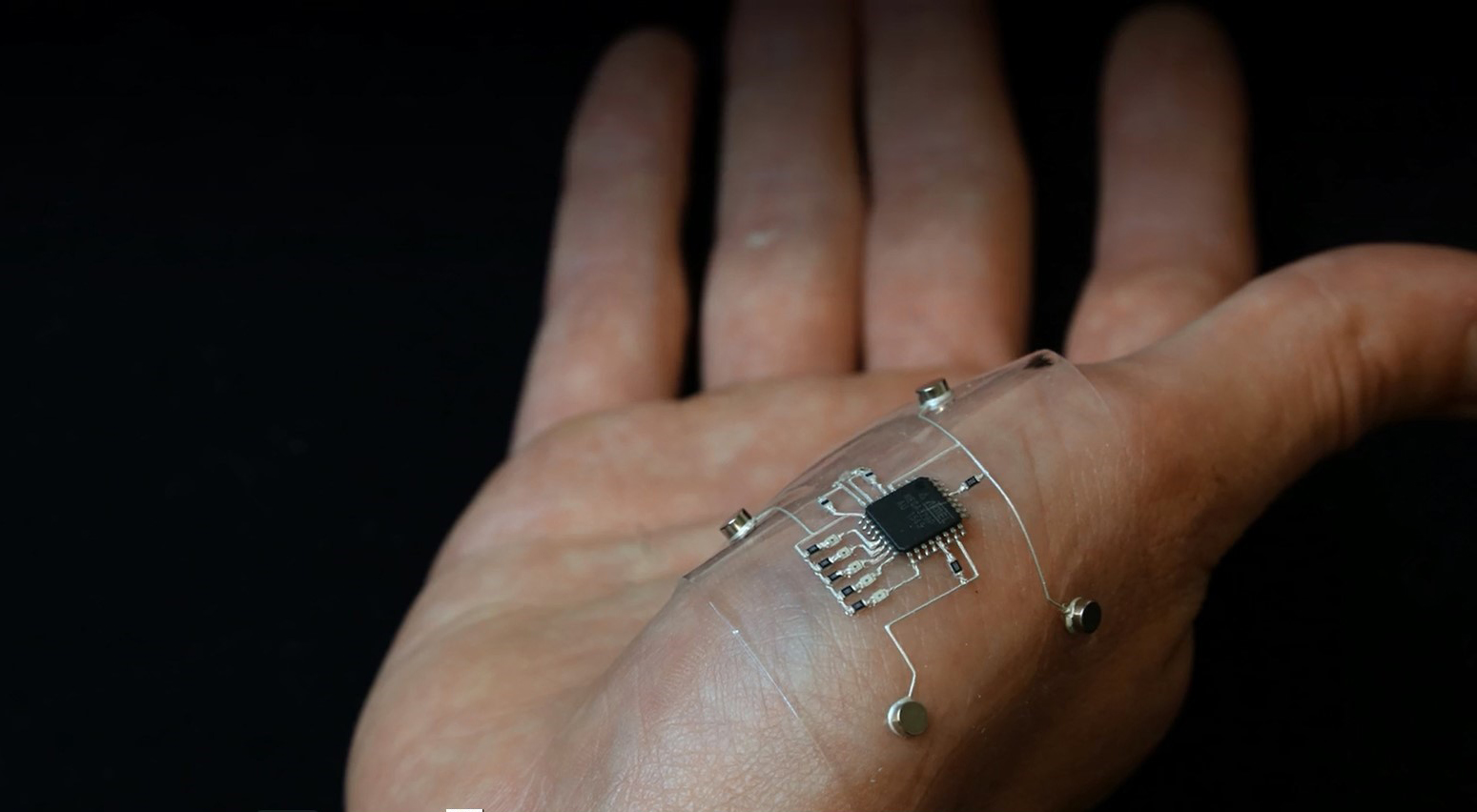

Tactile sensors are already embedded in countless technologies, from robotic hands to medical prosthetics and smart wearables. But existing sensors often face trade-offs: expand the sensing range and you lose sensitivity, increase sensitivity and you lose stability. The auxetic approach upends that equation. By harnessing negative Poisson’s ratio behavior, these 3D-printed structures amplify even subtle pressure signals while remaining robust enough for real-world integration.

The team validated their approach with two powerful demonstrations. The first was a tactile array capable of spatial pressure mapping—imagine a robotic hand that can not only grip but classify objects by touch alone. The second was a smart insole system that could monitor gait patterns and detect pronation types, providing real-time insights into mobility and health. In both cases, the auxetic sensors delivered performance conventional porous structures could not match, maintaining accuracy even when confined within rigid housings like shoe layers.

The implications go far beyond insoles and lab tests. These auxetic-based tactile sensors could become standard components in rehabilitation devices, advanced prosthetics, immersive gaming systems, and human-robot collaboration platforms. Because the geometry, not the material, drives performance, the design can be customized without changing the underlying base substances—meaning truly personalized sensors for individual needs. Additive manufacturing makes it possible to scale production, bringing bespoke tactile interfaces into everyday consumer products.

This research is a reminder that sometimes the future of technology doesn’t come from new materials or faster chips, but from reimagining structure itself. By exploiting the hidden potential of geometry, engineers are reshaping how machines and humans sense the world—and how we might build a generation of devices that are more responsive, more adaptive, and more human-like in their touch.

For more on breakthroughs in sensing and robotics, see:

How 3D-Printed Metamaterials Are Reinventing Wearables

The Next Frontier in Human-Machine Touch