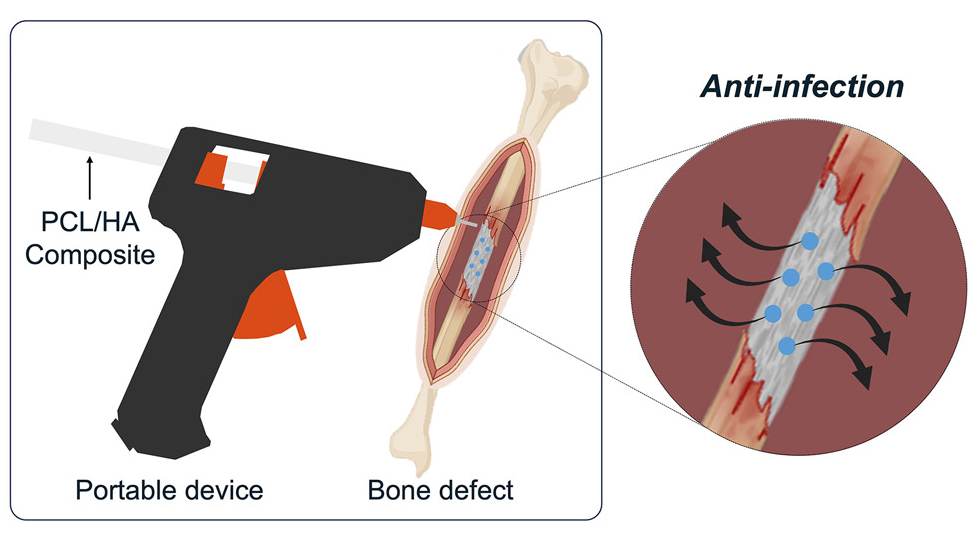

Imagine a surgeon standing over a complex fracture, not with a tray of pre-made implants but with something that looks like a glue gun—only instead of glue, it prints living scaffolds that function like bone. With a squeeze of the trigger, the surgeon literally rebuilds the skeleton in real time, layer by layer, tailored perfectly to the patient’s unique injury. What sounds like medical science fiction is now a very real possibility, thanks to a new handheld 3D printing device developed by a collaboration of researchers in Korea, the U.S., and top institutions like MIT and Harvard.

The device, revealed in Device on September 5, 2025, could mark a turning point in orthopedic medicine. Unlike current implants, which are pre-fabricated and often limited by shape and fit, this portable tool allows surgeons to print bone-like structures directly inside the operating room. For trauma patients, soldiers in the field, or those suffering catastrophic fractures, this could mean the difference between prolonged disability and rapid recovery.

How It Works

The handheld printer extrudes a composite material made from polycaprolactone (PCL), a soft biodegradable plastic, and hydroxyapatite (HA), a synthetic analog of the mineral found in bone. The combination is both biocompatible and osteoinductive, meaning it doesn’t just fill the gap—it actively encourages new bone growth and blood vessel formation. Surgeons can adjust the ratio of PCL to HA, tuning the implant’s strength, flexibility, and degradation rate to the patient’s specific needs.

During testing in rabbits, the device repaired severe femur fractures more effectively than conventional bone cement. After just 12 weeks, the printed scaffolds had not only integrated but also promoted stronger healing, with no infections or tissue complications. To further reduce risk, the team embedded antibiotics in the printed material, releasing them gradually at the fracture site to fend off bacteria during the vulnerable post-surgery phase.

Why This Is a Game-Changer

Traditional implants—whether metal, ceramic, or even 3D printed in advance—require extensive preoperative planning. They work well for straightforward injuries but fall short when faced with irregular fractures that don’t conform to standard shapes. The handheld printer removes that constraint. By letting doctors “draw” the implant directly into the defect, it provides a custom solution for every patient, no scanning or modeling required.

Equally important, the material is temporary. As the implant degrades, it is replaced by the patient’s own regenerating bone, eliminating the long-term complications often seen with permanent hardware. It’s a paradigm shift: implants that heal themselves out of existence.

From Rabbits to Humans

Of course, hurdles remain. So far, the technology has only been tested in animals. Scaling up to humans will require rigorous trials, regulatory approval, and validation that the device can be sterilized and standardized for surgical use. But if successful, the impact could ripple far beyond hospitals. Imagine field hospitals in disaster zones or military settings equipped with a printer that lets medics patch shattered bones on-site. Or consider its use in space, where astronauts could carry a lightweight printer instead of heavy medical equipment to handle emergencies millions of miles from Earth.

The handheld bone printer may not be in hospitals tomorrow, but it signals a provocative new direction: one where the line between machine, surgeon, and biology blurs. Surgeons won’t just be repairing bones—they’ll be manufacturing them in real time.

For further reading:

- 3D-Printed Organs: The Next Frontier in Transplant Medicine

- How Bioprinting Is Rewriting the Rules of Regenerative Medicine