For centuries, metallurgy has been a slow, brute-force art—smelting, mixing, hammering, and hoping the end product has the right properties. But Caltech scientists have just detonated that tradition with a breakthrough that turns metalmaking into a precision craft, letting researchers dial in alloy compositions like a DJ spinning tracks.

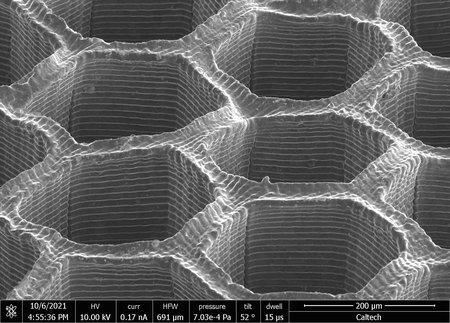

Their new approach, an extension of hydrogel-infusion additive manufacturing (HIAM), doesn’t just make parts—it engineers metal at the atomic scale. The process starts with a 3D-printed hydrogel scaffold, which is soaked in metallic salt solutions. The hydrogel burns away in a high-heat calcination process, leaving behind metal oxides. Then, under a hydrogen-rich environment, oxygen is stripped out and the final alloy emerges—dense, strong, and shaped exactly as designed.

The real magic? Absolute control over the ratios of different metals. Unlike traditional metallurgy, where composition changes are slow and imprecise, this method can instantly produce, say, a Cu12Ni88 alloy that’s nearly four times stronger than a more copper-heavy mix—without changing the shape or requiring new tooling.

Transmission electron microscopy revealed another surprise: this process creates ultra-uniform crystal structures studded with nanoscale oxide interfaces, hidden strength-boosters that make the alloy tougher than expected. In effect, HIAM makes metal that’s both purer and more complex than what standard foundries can deliver.

It’s a seismic shift in thinking—strength isn’t just about grain size anymore. Composition, nanoscale architecture, and manufacturing method now share equal billing. The implications ripple far beyond lab experiments: aerospace components tailored for extreme stress points, surgical implants with perfect biocompatibility, and industrial parts fine-tuned for wear resistance could all come from the same printer.

Metallurgy, it seems, just got a software upgrade.

Related Stories:

- MIT Engineers 3D-Print High-Performance Metals Using Nanoparticle Inks

- NASA Tests 3D-Printed Superalloys Built for Extreme Heat