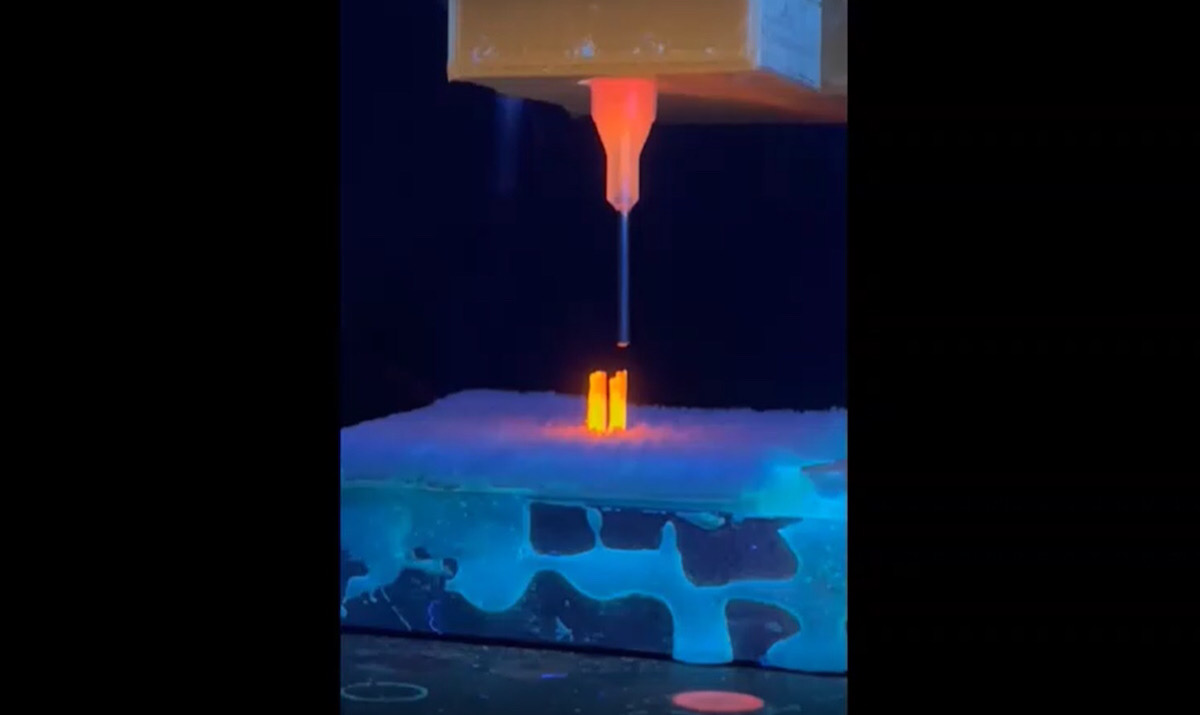

Launcher conducts a hot fire test for its 3D-printed Engine-2 rocket engine in the E Test Complex at NASA’s Stennis Space Center.

Chinese start-up SpaceTai has claimed its 3D printing technology is capable of slashing rocket production costs by as much as 80 percent.

Although a relatively new arrival on the space scene, SpaceTai says it can manufacture almost all its rocket parts using its self-developed 3D printers in order to cut costs.

With its first suborbital test flight slated for 2023, the firm could potentially challenge the likes of Elon Musk’s SpaceX, Rocket Lab, Orbex, Relativity Space, and others leveraging 3D printing in the race to space in years to come.

Continue reading… “CHINESE START-UP ON A MISSION TO CUT ROCKET PRODUCTION COSTS BY 80% WITH 3D PRINTING”