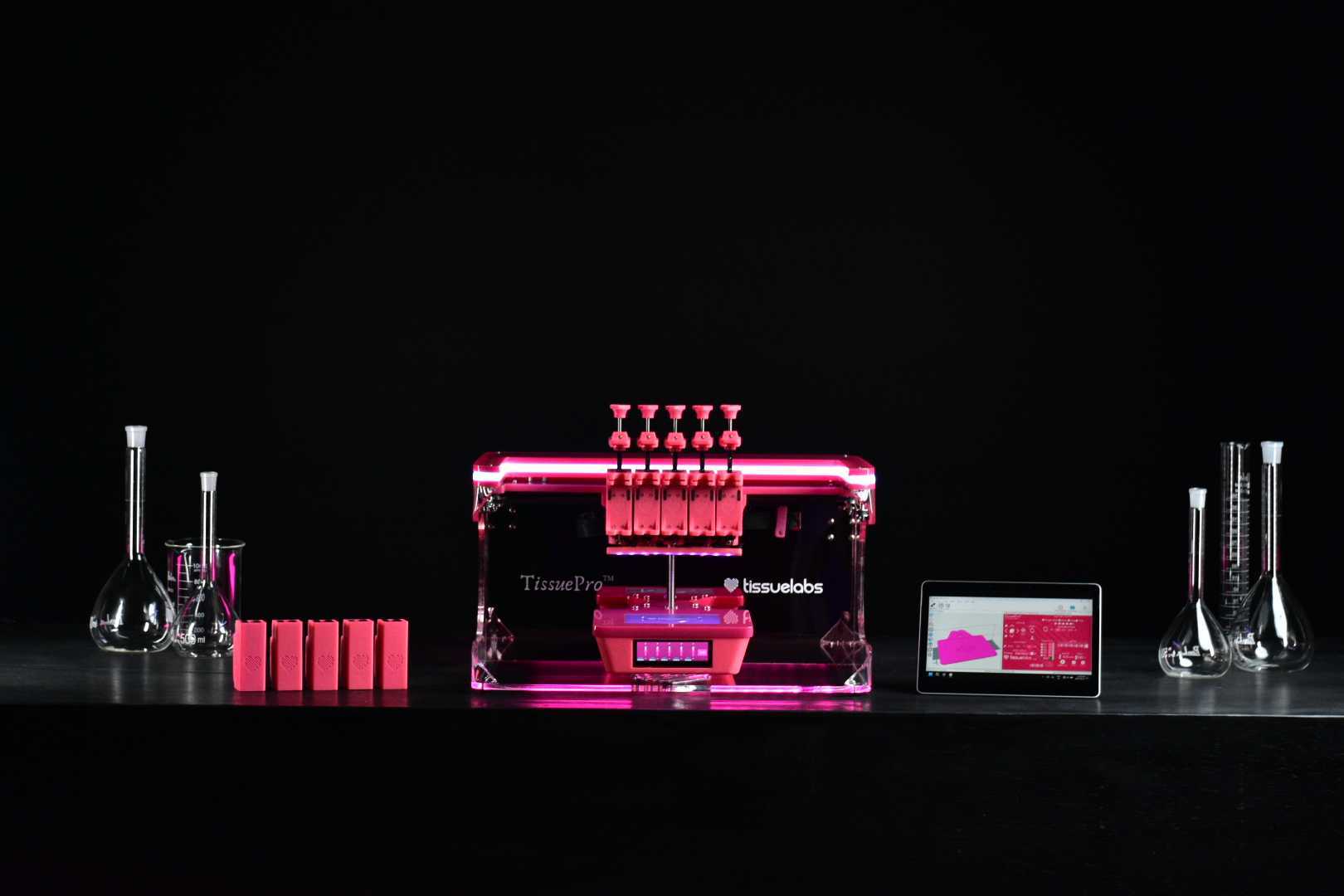

Swiss biotech company TissueLabs has announced the launch of its most advanced bioprinter to date, the TissuePro. Designed specifically for tissue engineering and regenerative medicine, TissuePro introduces a significant leap forward in multi-material precision printing, automation, and versatility, surpassing the capabilities of the company’s earlier models.

TissuePro is the successor to TissueStart, TissueLabs’ entry-level bioprinter, which is currently used in over 300 laboratories across more than 30 countries. While TissueStart served as an accessible platform for researchers beginning their bioprinting journey, TissuePro is built for scaling up operations and tackling more sophisticated applications. These include complex tissue constructs, organ-on-a-chip systems, vascularized structures, and other frontier challenges in regenerative medicine.

“TissuePro is everything we’ve learned, reinvented, and reimagined,” said Dr. Gabriel Liguori, Founder and CEO of TissueLabs. “If you loved TissueStart, get ready. You’re about to fall in love all over again.”

At the core of TissuePro is Mixtrusor, TissueLabs’ proprietary extrusion system that enables simultaneous mixing and deposition of multiple bioinks. It features five piston-based extruders, providing highly precise control—down to 0.1 microliters—over each material. This design offers a substantial improvement over traditional pressure-based systems, which often require continuous adjustment and lack the same level of fine control.

The advanced printing capabilities of TissuePro support coaxial and triaxial printing, techniques that allow multiple bioinks to be printed concentrically within a single strand. This enables researchers to produce intricate, heterogeneous tissues with layered structures and compositional gradients—more closely mimicking the complexity of human biology.

To further enhance versatility, TissuePro includes a light-curing system with five distinct wavelengths, expanding the range of compatible biomaterials. Both the printheads and the print bed feature temperature control ranging from 4°C to 60°C, making the system suitable for printing with both synthetic and natural materials. Additionally, automated multi-head printing streamlines workflows and ensures more consistent and reproducible results.

TissuePro is built with a broad range of uses in mind. Beyond its core focus on regenerative medicine, the bioprinter is ideal for drug development, cancer research, organ-on-a-chip modeling, cultivated meat production, and even soft robotics—any field requiring high precision, flexibility, and material compatibility. Pre-orders for the system are now open, with the first shipments expected to begin in August 2025.

The release of TissuePro also reflects TissueLabs’ ongoing evolution. Founded in Brazil, the company relocated its headquarters to Switzerland to be closer to Europe’s thriving biotech and innovation ecosystem. Under the guidance of Dr. Liguori, a surgeon-turned-entrepreneur, TissueLabs has expanded its portfolio to include not only bioprinters but also biomaterials and supporting software tools.

With the introduction of TissuePro, TissueLabs is reaffirming its mission to accelerate the development of lab-grown tissues and organs, and to make state-of-the-art bioprinting tools more accessible to researchers and labs around the globe.

By Impact Lab