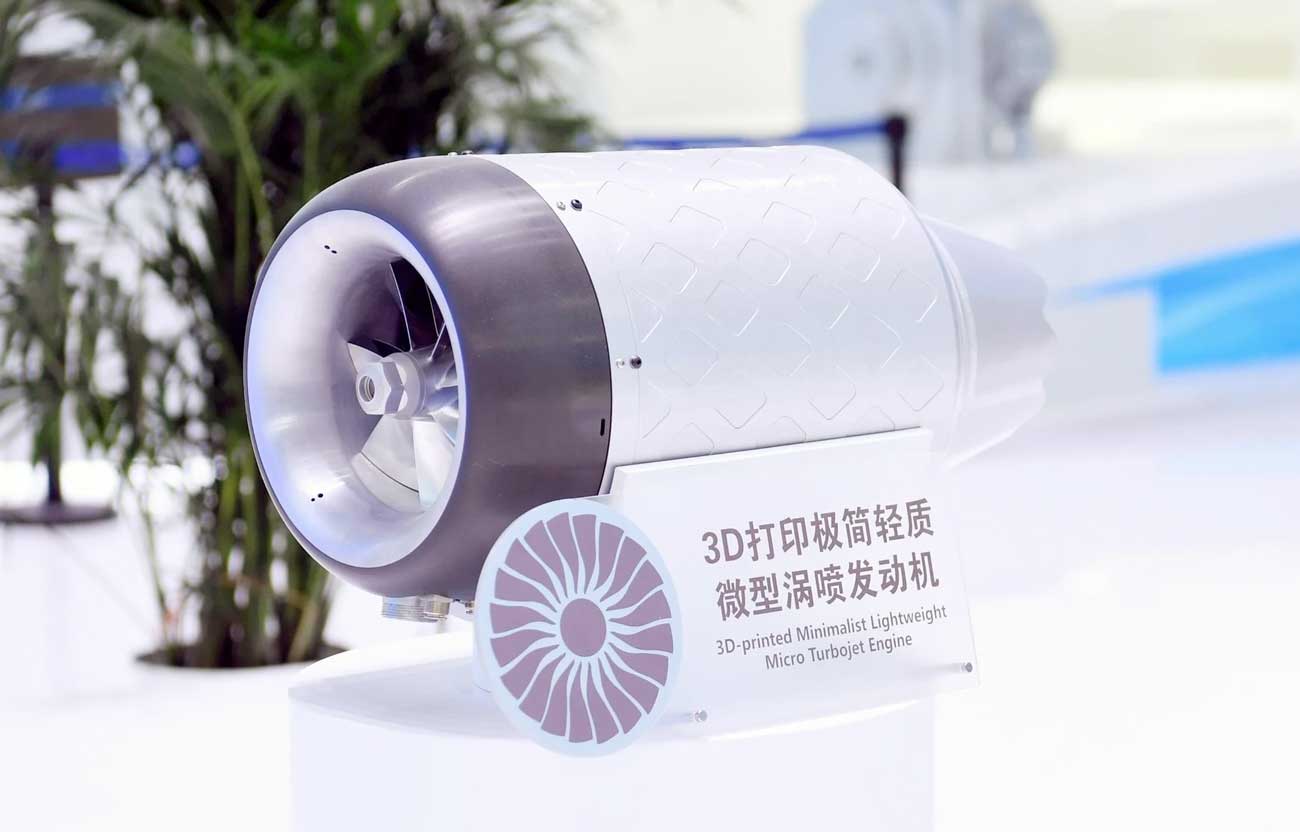

China has successfully completed a real-flight test of a fully 3D-printed miniature turbojet engine, marking a significant milestone in aerospace engineering. The flight took place in Inner Mongolia and reached an altitude of up to 4,000 meters. The engine, developed by the Aero Engine Corporation of China (AECC), is the first in the country to be entirely produced using additive manufacturing and to deliver a thrust of 160 kilograms.

This breakthrough was achieved through a combination of advanced multi-disciplinary topology optimization and 3D printing technology. The design process focused on reducing material in low-stress areas, which significantly reduced the engine’s weight without compromising strength or functionality.

Beyond structural optimization, AECC applied an integrated component design approach, eliminating many traditional manufacturing steps. This not only simplified the assembly process but also enhanced the engine’s thermal and aerodynamic efficiency. The result is a compact and lightweight propulsion unit with performance optimized for demanding flight conditions.

Before being cleared for airborne testing, the engine underwent a comprehensive series of ground tests. Engineers assessed its thermal stability, thrust output, and mechanical durability across the full operational lifespan. All parameters remained well within tolerance, confirming the engine’s reliability and performance under stress.

This successful flight test marks a key achievement in China’s efforts to advance additive manufacturing in high-performance aerospace systems. It demonstrates that 3D printing can move beyond prototype development and be applied in the production of fully functional and highly stressed engine components.

The project lays the groundwork for future innovation in aircraft propulsion and represents a significant step toward more efficient, cost-effective, and scalable production methods in the aviation sector.

By Impact Lab