It sounds like something straight out of a sci-fi novel—colonists on the Moon building cities from nothing but sunlight and lunar dirt. But in a laboratory in Hefei, China, engineers have turned this fantasy into working hardware.

The Deep Space Exploration Laboratory has developed a 3D-printing-style machine that takes lunar regolith—the powdery soil covering the Moon—and uses concentrated sunlight to melt it into tough, functional bricks. No glue. No additives. No supply rockets hauling cement from Earth. Just heat, dust, and ingenuity.

Here’s how it works: a parabolic reflector gathers intense solar radiation, funnels it through fiber optic bundles, and focuses it until the light intensity is over 3,000 times stronger than normal sunlight. At that point, the temperature soars above 1,300°C, hot enough to fuse the Moon’s gritty surface into solid blocks. The bricks can then be stacked into protective walls, roadways, and landing pads—essential infrastructure for a permanent lunar settlement.

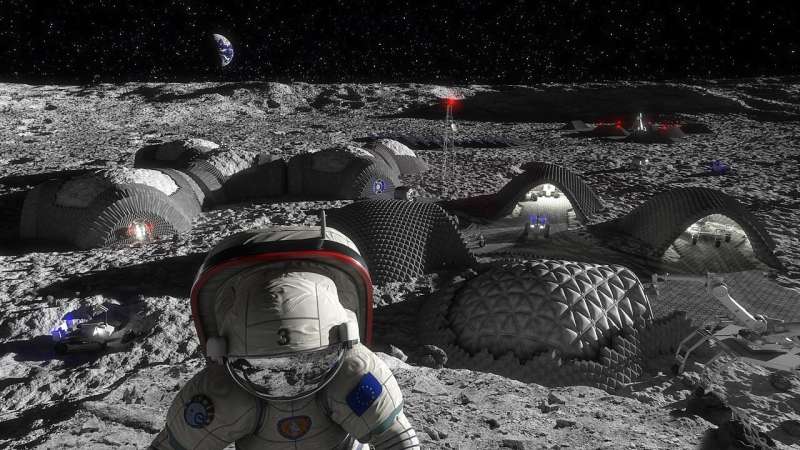

These lunar bricks aren’t meant to hold air pressure—they’ll serve as a defensive skin around pressurized habitats made of rigid or inflatable modules. Think of it as a medieval castle wall, except the castle is a dome full of oxygen and the moat is the endless lunar vacuum. They’ll shield residents from radiation, micrometeoroids, and the occasional cosmic pebble flying in at interplanetary speeds.

The project wasn’t simple. Different parts of the Moon have different soil compositions, so the team had to create several versions of simulated regolith to ensure their system could handle the variety. And transmitting concentrated solar energy through fiber optics without losing efficiency required years of refinement.

Senior engineer Yang Honglun says the real beauty of the system is its independence: “We bring no additives. We use only what’s already there.” The long-term plan is a robotic construction crew capable of making bricks on demand, assembling modular components, and stress-testing the results under the Moon’s extreme conditions.

The first durability tests will happen closer to home. Later this year, simulated lunar bricks will hitch a ride on China’s Tianzhou 8 cargo spacecraft to the national space station, where astronauts will expose them to the realities of space—temperature swings, radiation, and micrometeoroid impacts. If the tests hold up, the blueprint for lunar city construction will be in hand.

When the first Moon settlers land for good, they may not arrive with stacks of pre-built modules. Instead, they’ll come with a solar-powered oven, a handful of robots, and the knowledge that their homes are literally underfoot.

Similar Reads:

- NASA’s Artemis Team Eyes Moon Bricks for Future Habitats

- European Space Agency Tests 3D-Printing with Lunar Soil Simulant