By Futurist Thomas Frey

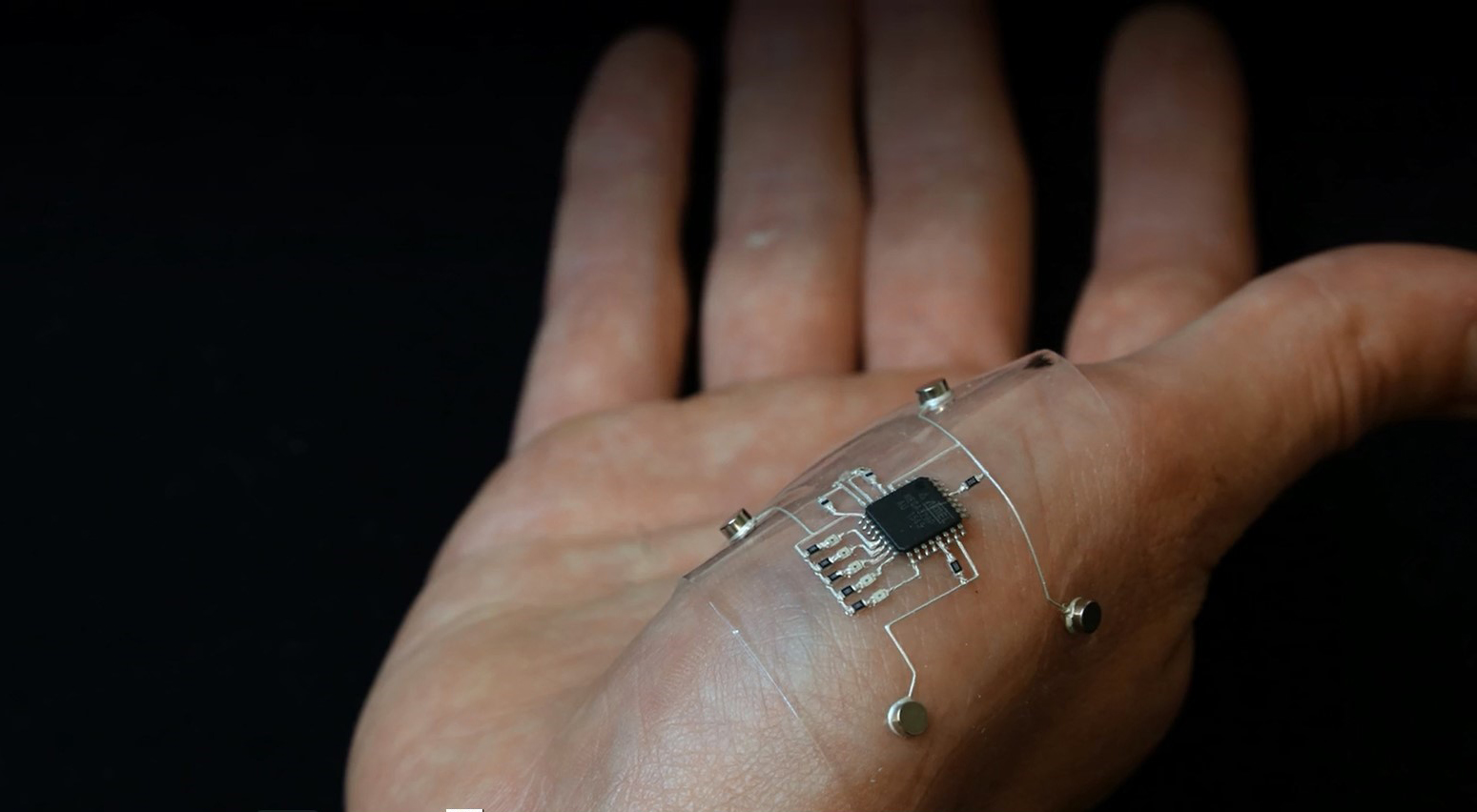

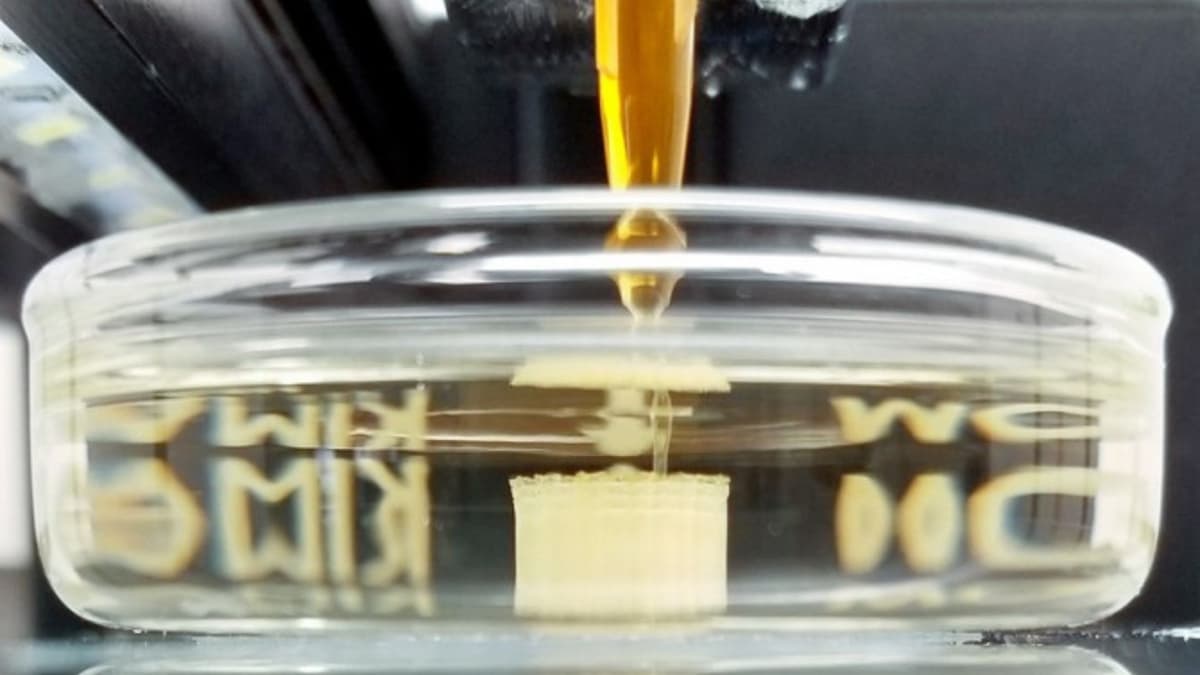

The moment we’ve long awaited is here: 3D printers that build tissues inside the body rather than on a bench. The latest innovation—implantable bio-printers that operate in situ within living bodies—marks a rupture in medicine. We are no longer limited to replacing damaged tissues with donor grafts or synthetic implants; we are now capable of growing new structures inside the patient, perfectly integrated with existing biology. With this leap, the boundary between surgery and regeneration collapses.

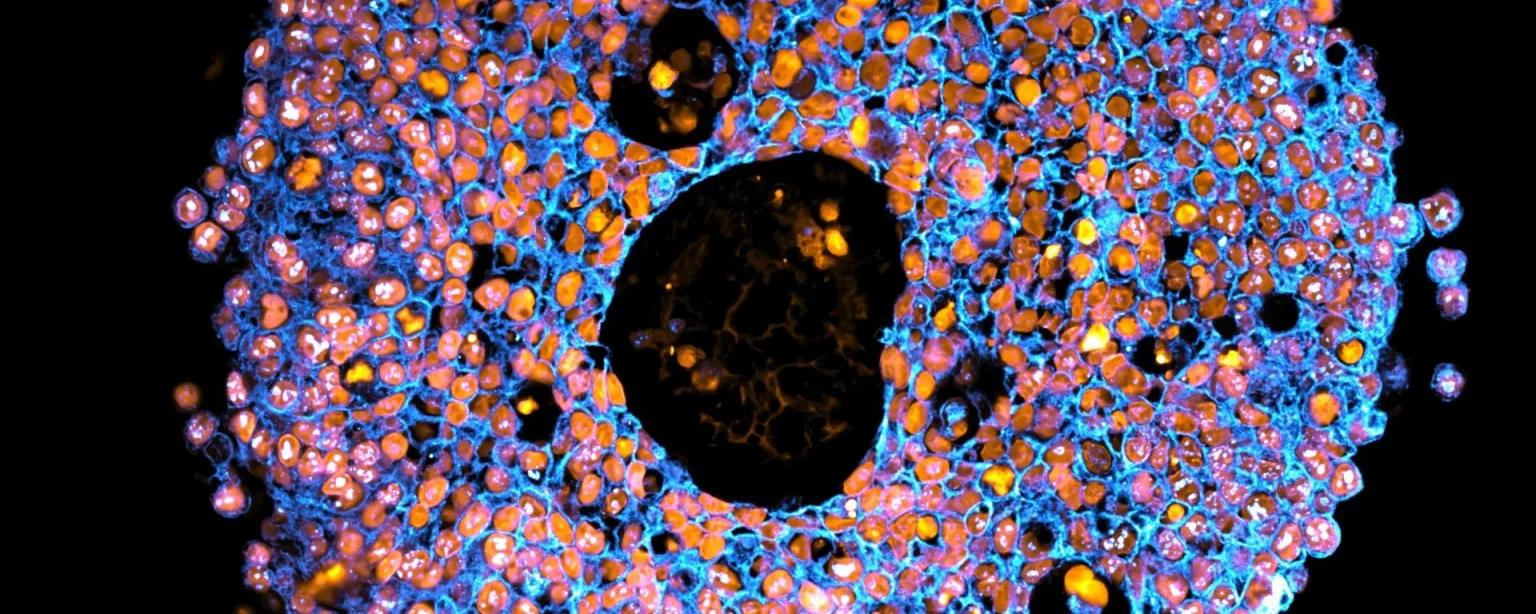

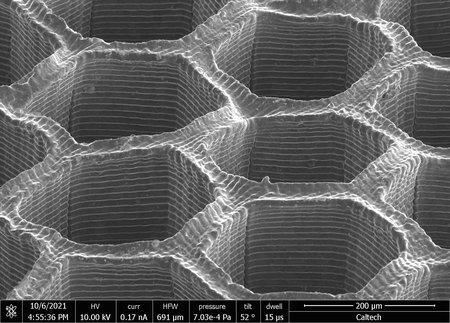

These internal bio-printing systems use biocompatible inks, stem cell scaffolds, and robotic micro-nozzles guided by imaging and AI to deposit layers of tissue in precise anatomical contours. A surgeon no longer stitches a patch onto a defect; the printer weaves new material layer by layer, cell by cell, within the wound site itself.

Continue reading… “In-Body 3D Printing: The Future of Healing From Within”