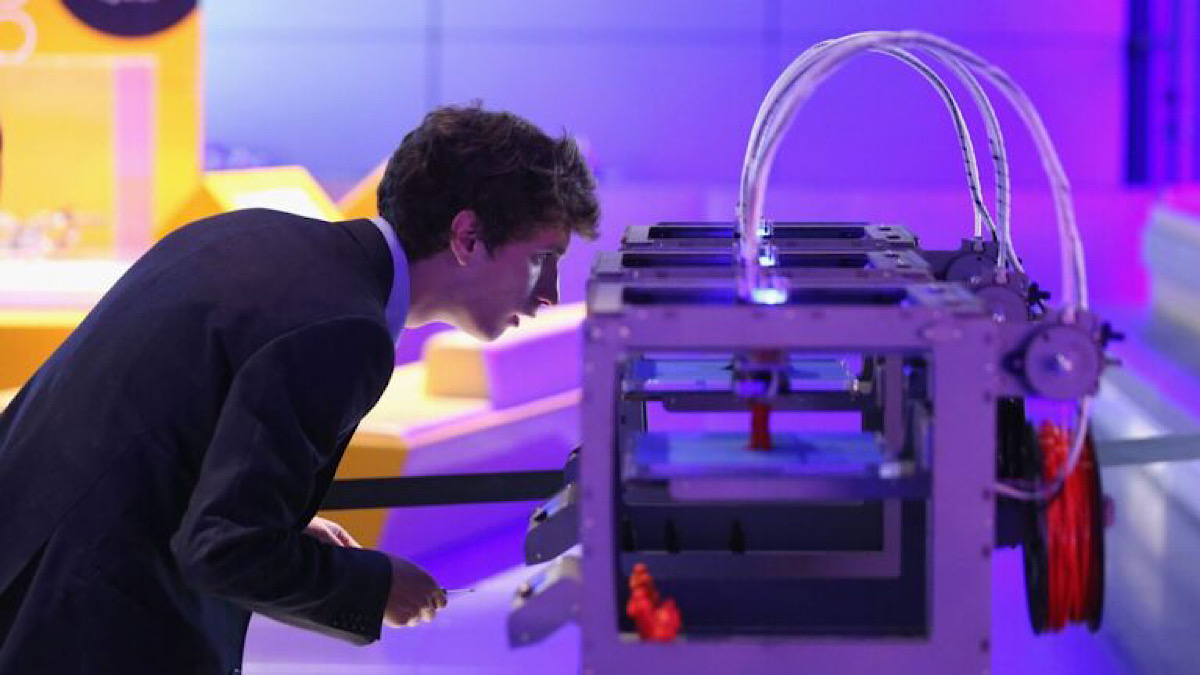

A technician checks on a 3D printer as it constructs a model human figure in the exhibition ‘3D: printing the future’ in the Science Museum on October 8, 2013 in London, England. The exhibition, which opens to the public tomorrow, features over 600 3D printed objects ranging from: replacement organs, artworks, aircraft parts and a handgun.

By Michael Leidig

The idea, however, has been beset with technical problems that have, to date, limited the type of organs that can be printed.

With too few organs to go around to satisfy the demand for transplants, scientists are now pinning their hopes on the possibility of 3D-printing technology.

In the United States alone there are an estimated 112,000 people currently waiting for urgent transplants and there is, therefore, plenty of demand for the possibility of 3D-printed organs.

The idea, however, has been beset with technical problems that have, to date, limited the type of organs that can be printed.

But researchers at the Stevens Institute of Technology, a private research university in New Jersey, are now pushing through these barriers by revamping a decades-old technique to reproduce any tissue type.

The work, led by Robert Chang, an associate professor in the mechanical engineering department at Stevens’ Schaefer School of Engineering & Science, could open up pathways for 3D printing any kind of organ at any time, even skin directly on an open wound.

Continue reading… “American Research Team Puts New Spin On Old Technique To Produce 3D-Printed Organs”