In a groundbreaking advancement that merges robotics, materials science, and origami, engineers at Princeton University have developed a shape-shifting material capable of moving, expanding, and responding to electromagnetic commands — all without motors or internal gears. This new class of metamaterial can be remotely controlled, functioning almost like a robot, yet is constructed entirely from passive components.

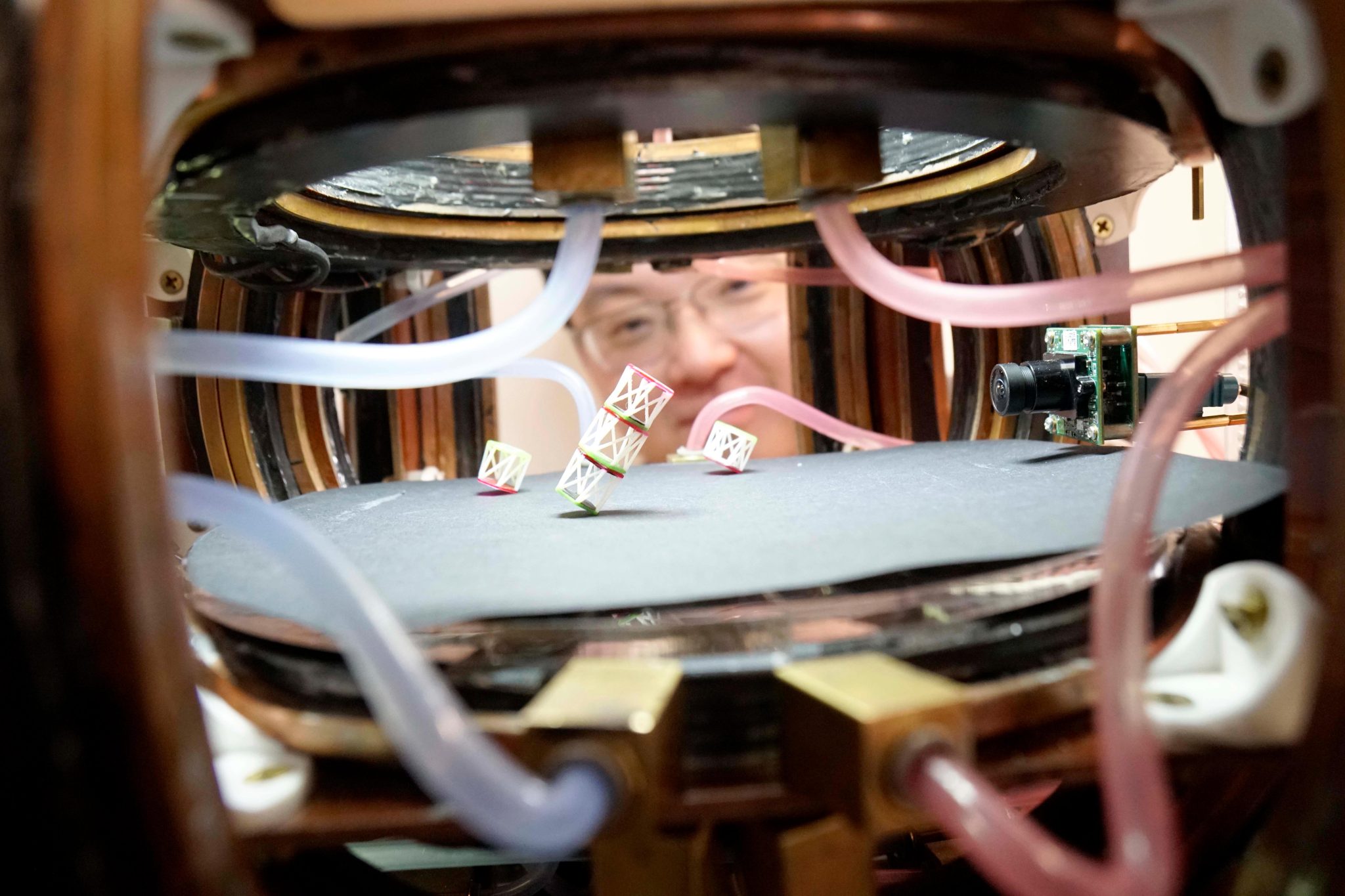

The research, published in Nature, introduces a metamaterial dubbed the “metabot,” which derives its unique capabilities from its structure rather than its chemical composition. Drawing inspiration from the traditional art of origami, the team designed the metabot to change shape and behavior in response to external magnetic fields.

Constructed using a blend of basic plastics and magnetically responsive composites, the metabot can bend, twist, expand, and contract in various ways. It’s powered and directed entirely through electromagnetic fields, which transmit energy and instructions simultaneously — eliminating the need for physical connections.

At the heart of the material is a repeating structure based on the Kresling pattern, a geometric form common in origami. Plastic tubes with specially designed support struts twist when compressed and compress when twisted. These tubes are arranged in mirrored pairs to create a chiral structure — a design that gives rise to asymmetric mechanical behavior. This configuration allows different segments of the metabot to react independently under magnetic control, enabling intricate, programmable movement.

The modular design allows for a high degree of mechanical complexity. The metabot can twist, shrink, or collapse in response to different sequences of electromagnetic signals. This behavior can even simulate hysteresis — where the material’s response depends on the sequence of applied forces — a phenomenon typically difficult to model.

Beyond robotics, the potential applications for this technology are vast. The researchers demonstrated its use in creating a thermoregulating surface that could switch between light-absorbing and reflective states, altering its temperature from 27°C to 70°C under sunlight. This feature could have applications in energy efficiency and environmental control.

The material also holds promise for medical applications. At the microscopic scale, prototypes created with laser lithography were as small as 100 microns — roughly the thickness of a human hair. Such micro-scale metamaterials could be used for targeted drug delivery or minimally invasive surgery, reaching areas of the body currently inaccessible to conventional robotic tools.

In addition, the technology may impact areas such as aerospace, soft robotics, adaptive antennas, optical devices, and even computational logic, by simulating logic gate behavior in physical form.

The Princeton team’s innovation presents a paradigm shift in how materials can be programmed to perform complex tasks without traditional mechanical components, opening up exciting possibilities in both science and engineering.

By Impact Lab