By Futurist Thomas Frey

The Complexity Crisis Nobody’s Preparing For

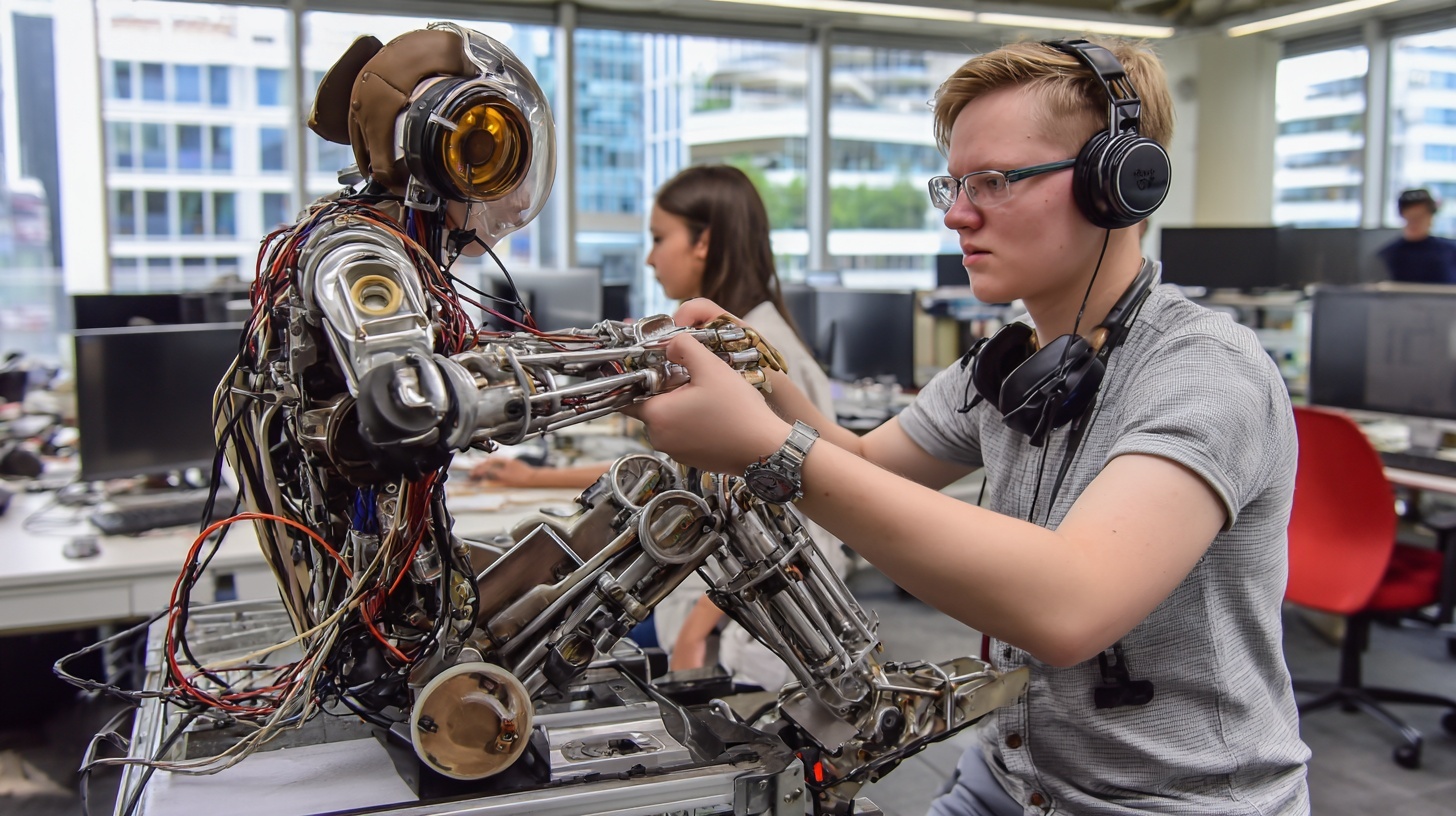

By 2040, you’ll own or interact with autonomous vehicles, humanoid robots, delivery drones, smart home systems, medical devices, and infrastructure so complex that when they break—and they will break—almost nobody will know how to fix them. We’re building a world of sophisticated machines faster than we’re training people to maintain them, and the gap between complexity and repair capability is widening catastrophically.

Here’s the uncomfortable truth: we’re imagining robots repairing robots, AI diagnosing AI, autonomous systems maintaining themselves. That’s the fantasy. The reality is a brutal 15-20 year transition period where machines break constantly, repair expertise is scarce, and downtime costs escalate exponentially because we built complexity faster than we built the maintenance culture to support it.

This isn’t a minor inconvenience. It’s an approaching crisis that will reshape labor markets, create massive business opportunities, and determine which technologies actually scale versus which ones fail because nobody can keep them running.

Why the Maintenance Gap Is Worse Than You Think

Complexity Explosion: Your autonomous car has more computing power than the Apollo spacecraft, more sensors than a commercial aircraft, and software updated over-the-air weekly. When something breaks, it’s not a simple mechanical failure—it’s a cascade of interacting systems requiring diagnostic expertise that barely exists.

Skill Shortage Accelerating: We’re not training maintenance technicians fast enough. Trade schools focus on yesterday’s technologies. By the time someone masters driverless car diagnostics, the technology has evolved three generations. The knowledge half-life is measured in months, not years.

Proprietary Lock-In: Manufacturers design products requiring proprietary diagnostic tools, specialized training, and authorized service centers. Right-to-repair gets crushed by complexity—even if you legally can fix your robot, you lack the tools, documentation, and expertise to actually do it.

Remote Diagnosis Fails: AI diagnostic systems help but can’t solve everything. When your humanoid robot stops working, remote diagnostics might identify the problem, but physical repair requires trained humans who understand robotics, AI systems, mechanical engineering, and electrical systems simultaneously.

The Brutal Transition: 2025-2040

Phase 1 (2025-2030): The Breaking Point Autonomous systems proliferate faster than maintenance infrastructure develops. Repair costs spike. Downtime becomes chronic. Early adopters discover their $50,000 robots break constantly and repair takes weeks because qualified technicians don’t exist locally. Manufacturers scramble to build service networks they didn’t plan for.

Phase 2 (2030-2035): Emergency Measures Crash training programs emerge. Community colleges offer six-month certifications in drone repair, robot maintenance, autonomous vehicle diagnostics. Quality varies wildly. Some graduates are competent; others are dangerous. Insurance companies start requiring certified maintenance to cover autonomous systems, creating credential inflation.

Phase 3 (2035-2040): Mature Ecosystem Robust maintenance culture finally develops. Specializations emerge—drone specialists, humanoid robot techs, autonomous vehicle diagnostics experts. AI-assisted repair becomes standard, with technicians using AR glasses showing step-by-step instructions. But we’ve lost a decade to the gap between deployment and maintenance capability.

What the New Maintenance Culture Actually Looks Like

Mobile Repair Networks: Independent technicians with vans full of diagnostic equipment travel to repair robots, drones, and autonomous vehicles on-site. Think Geek Squad meets high-tech manufacturing. These techs earn $100K+ annually because expertise is scarce and demand is massive.

Specialty Repair Shops: Neighborhood shops specializing in specific systems—one does drones, another does humanoid robots, a third handles autonomous vehicle sensors. Like auto mechanics, but requiring far more sophisticated knowledge.

Manufacturer Service Subscriptions: You don’t buy robots—you subscribe to them, with maintenance included. Manufacturers maintain ownership and handle all repairs because letting customers deal with maintenance leads to catastrophic failures and liability nightmares.

Remote-Assisted Repair: Technicians work with AI systems providing real-time diagnostic support and repair guidance through AR interfaces. The human handles physical work; the AI provides expertise and documentation.

Modular Repair Culture: Devices designed for field-replaceable modules rather than component-level repair. Swap the broken sensor array, motor assembly, or computing unit rather than diagnosing individual failures. Modules get sent back to manufacturers for refurbishment.

Community Repair Networks: Maker spaces, repair cafes, and community workshops where people share knowledge and tools for maintaining their devices. Not officially sanctioned, often violating warranties, but essential because authorized repair is too expensive or unavailable.

The Massive Opportunities

1. Training Academies: Create specialized programs training technicians in autonomous systems maintenance. Partner with manufacturers for certifications. Graduates have immediate high-paying jobs waiting.

2. Mobile Maintenance Services: Launch businesses providing on-site repair for drones, robots, autonomous vehicles. Serve geographic areas too small for manufacturers to cover directly.

3. Diagnostic Software Platforms: Build AI-assisted diagnostic tools helping technicians identify and fix problems faster. Sell subscriptions to independent repair shops.

4. Refurbishment Operations: Collect failed modules from field repairs, refurbish them at scale, and resell at margins higher than new manufacturing.

5. Maintenance Marketplace: Create platforms connecting device owners with qualified technicians, handling scheduling, payment, and quality assurance. Uber for robot repair.

The Uncomfortable Reality

We’re building a world that breaks constantly and that almost nobody can fix. Autonomous vehicles will strand people when sensors fail. Delivery drones will crash because maintenance was deferred. Humanoid robots will become expensive paperweights when motors burn out and replacements take months.

The maintenance culture will eventually develop—but the transition period will be brutal, expensive, and chaotic. The winners will be people who see this coming and position themselves as the experts who can actually fix the sophisticated systems everyone else is deploying blindly.

Final Thoughts

By 2040, we’ll have a mature maintenance culture supporting autonomous systems—mobile repair networks, specialized technicians earning six figures, AI-assisted diagnostics, and sophisticated training pipelines. But between now and then, we face a decade-plus of systems breaking faster than we can fix them, creating opportunities for those who build the maintenance infrastructure we desperately need.

After all, someone has to repair the robots before the robots can repair themselves. That transition creates one of the largest labor market opportunities of the next 15 years—if you’re willing to get your hands dirty fixing machines most people don’t understand.

Related Articles:

The Rise of Robot Money: When Machines Start Earning, Spending, and Investing Without You

When Machines Start Talking to Each Other: The Bizarre Choreography of Autonomous Everything