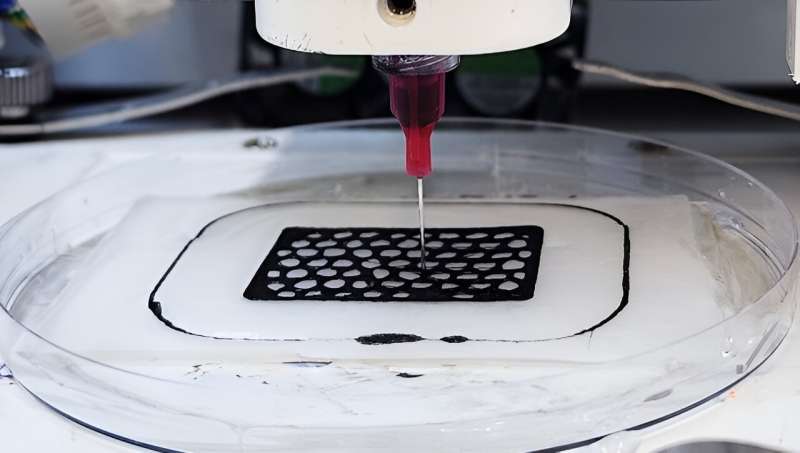

Researchers at MIT have successfully created durable, interlocking glass bricks using 3D printing technology. These reusable bricks, which can withstand loads similar to concrete blocks, offer a promising sustainable alternative for future construction.

The engineers behind this innovation aim to promote a circular construction process by using recycled glass. The glass can be reshaped or repurposed at the end of a building’s life cycle, significantly reducing waste. In the future, these 3D-printed glass blocks could be used for building facades or interior walls, offering an eco-friendly substitute for traditional concrete.

Continue reading… “MIT Develops 3D-Printed Glass Bricks for Sustainable Construction”