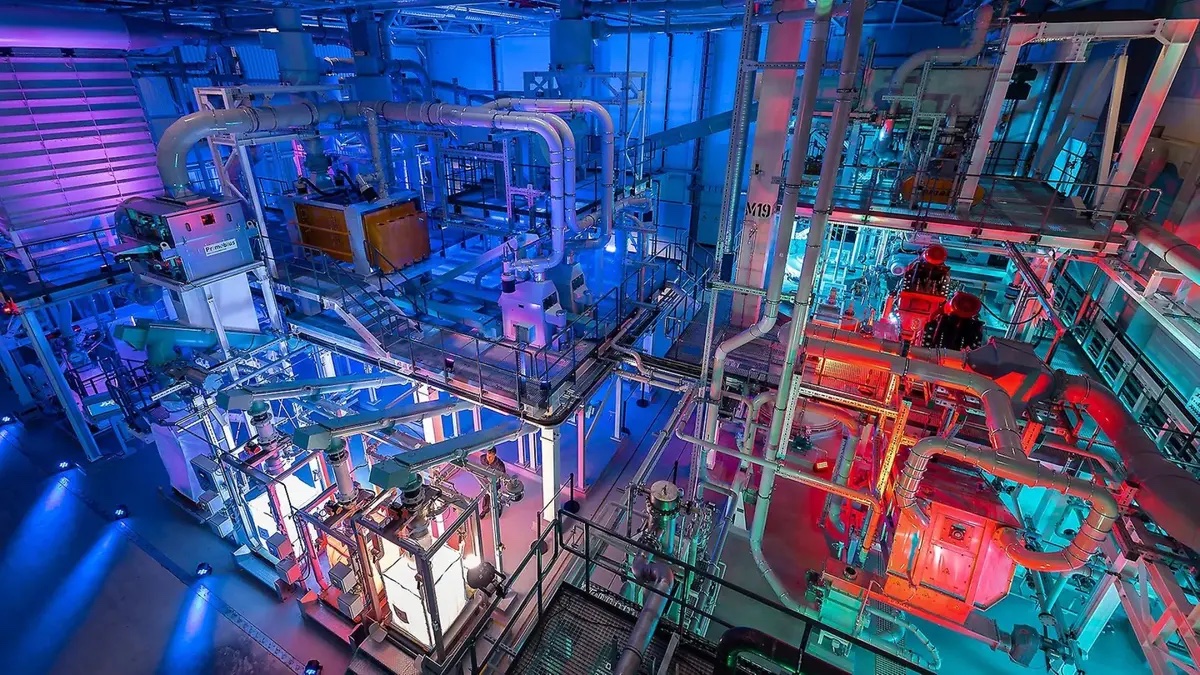

Mercedes-Benz has made a groundbreaking advancement in sustainable electric vehicle (EV) production by opening Europe’s first integrated battery recycling facility in Kuppenheim, Germany. This state-of-the-art plant, representing an investment of tens of millions of euros, is designed to process 2,500 tonnes of batteries annually, producing enough recycled materials to manufacture modules for over 50,000 new EVs. The facility employs a mechanical-hydrometallurgical process that achieves an impressive 96 percent recovery rate of valuable materials. “This innovative technology enables us to recover valuable raw materials from the battery with the highest possible degree of purity,” said Jörg Burzer, Board Member responsible for Production at Mercedes-Benz Group AG.

Innovative EV Recycling Process

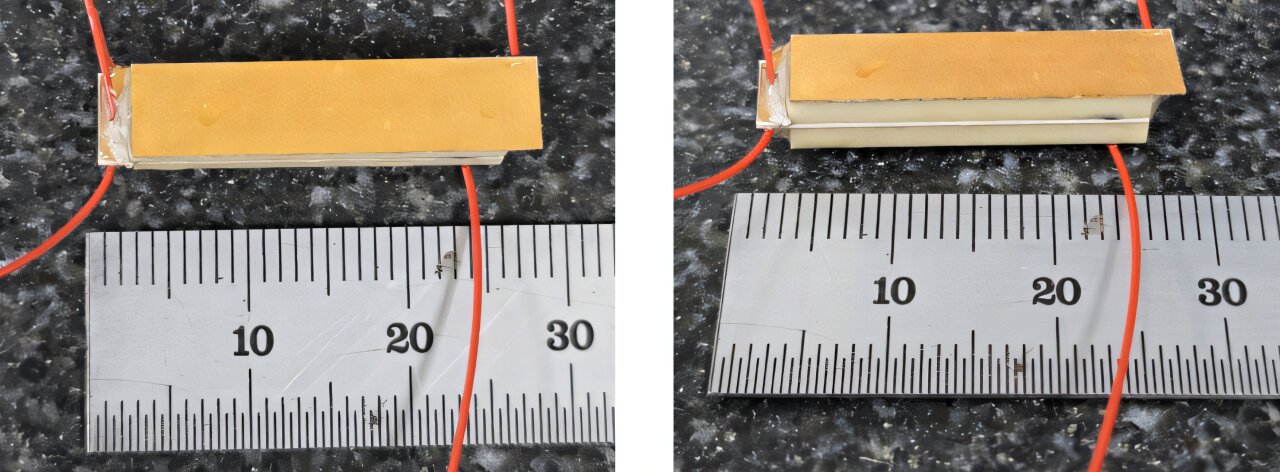

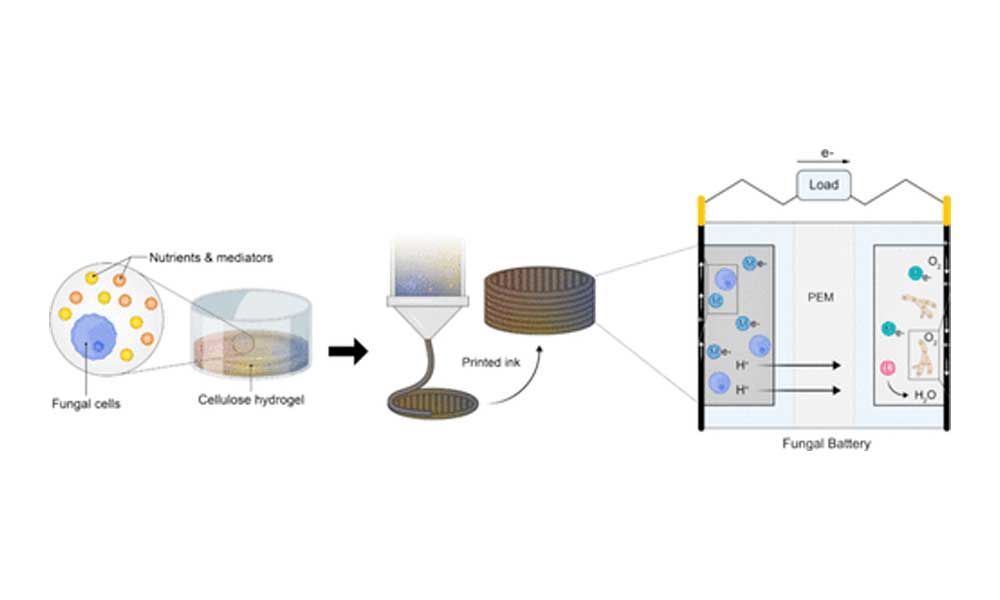

The facility’s recycling process begins with the mechanical separation of battery components, followed by the hydrometallurgical treatment of “black mass,” containing valuable metals like cobalt, nickel, and lithium. These metals are then refined to battery-grade quality, allowing them to be reused in new Mercedes-Benz EVs. The plant operates at up to 80°C, an energy-efficient temperature that reduces both energy consumption and waste, and it’s powered entirely by green electricity. The 6,800-square-meter roof of the facility also houses a 350-kilowatt photovoltaic system, making the plant carbon-neutral.

Continue reading… “Mercedes-Benz Opens Europe’s First Integrated Battery Recycling Plant for EV Sustainability”