American physicist Michio Kaku says CAPSTONE mission overcomes ‘the cost of space travel’

American physicist and author Michio Kaku says 3D-printed rockets has lowered the cost of space exploration ten-fold.

NASA’s mission to the moon has returned – but this time, with a modern tech twist.

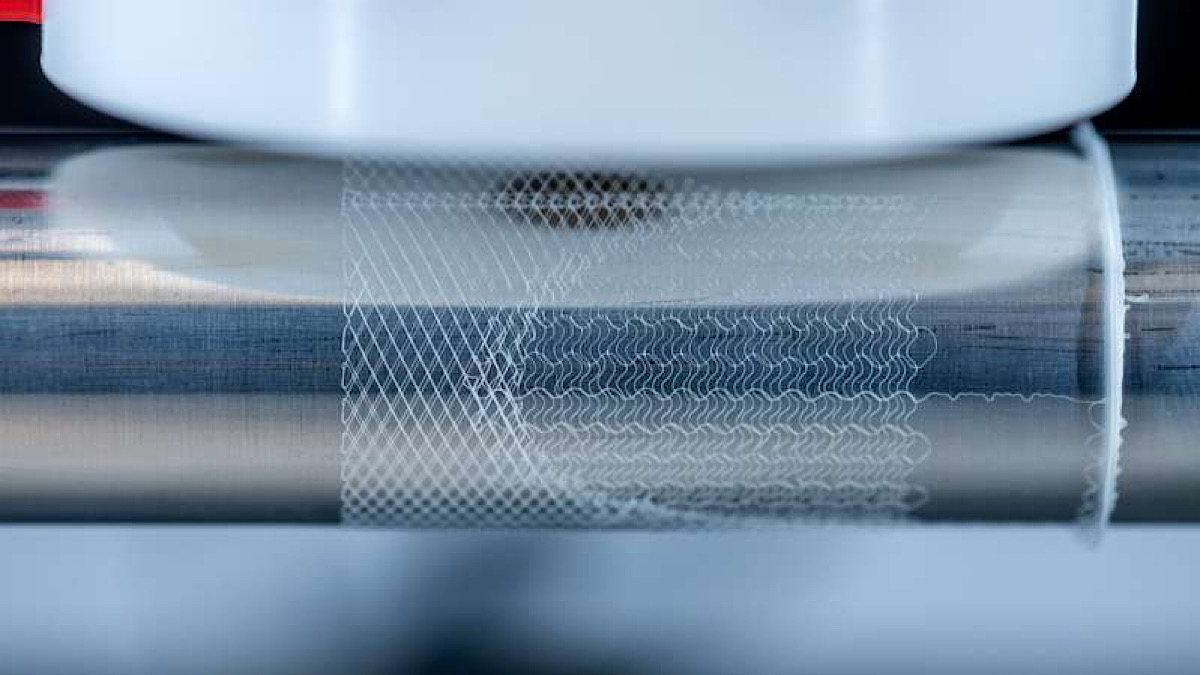

A 3D-printed satellite the size of a microwave oven was launched into space Tuesday, embarking on a new path around the moon in hopes of retrieving new information for future astronaut exploration.

American physicist and author Michio Kaku called the CAPSTONE CubeSat launch a “game changer” for spaceflight on “Varney & Co.” Thursday.

“Space travel has been haunted by a dirty four-letter word: cost,” Kaku told FOX Business’ Stuart Varney. “It costs $10,000 to put a pound of anything into orbit around the Earth. That’s your weight in solid gold. That’s the cost of space travel.”

Continue reading… “3D-PRINTED NASA SATELLITE MARKS ‘GAME-CHANGER’ FOR SPACE EXPLORATION: MICHIO KAKU”